Footwear designed specifically for skateboarding typically incorporates features that enhance performance and durability. These specialized shoes often include reinforced stitching, durable outsoles for grip, and cushioning to absorb impact. An example would be a low-profile shoe with a vulcanized rubber sole and a suede upper, offering board feel and resilience to wear and tear from skateboarding maneuvers.

The importance of appropriate footwear in skateboarding cannot be overstated. Specialized designs provide superior grip, enhancing board control and reducing the risk of slippage. Reinforcement in high-wear areas extends the lifespan of the shoe, offering better value for money and reducing the frequency of replacement. Historically, skaters have modified standard footwear to meet their needs, leading to the development of purpose-built designs that offer improved protection and performance.

The following sections will delve into specific aspects of these specialized designs, covering material science, construction techniques, and the impact of design choices on skateboarding performance, offering detailed insights into what constitutes high-quality and effective skateboarding footwear.

Guidance on Selection and Maintenance

This section provides essential guidance for selecting appropriate footwear for skateboarding and maintaining its condition to maximize performance and longevity.

Tip 1: Prioritize Sole Construction: Vulcanized soles offer optimal board feel and grip, crucial for executing tricks. Examine the sole’s tread pattern for adequate traction before purchase.

Tip 2: Assess Upper Material Durability: Suede and leather uppers provide abrasion resistance, extending the shoe’s lifespan under the stresses of skateboarding. Consider reinforced stitching in high-wear areas.

Tip 3: Evaluate Cushioning and Support: Adequate cushioning absorbs impact during landings, reducing the risk of injury. Look for shoes with padded collars and tongues for enhanced ankle support.

Tip 4: Ensure Proper Fit: A snug but not restrictive fit is essential for board control. Account for sock thickness when trying on footwear to guarantee comfort during skateboarding sessions.

Tip 5: Regularly Clean Footwear: Remove dirt and debris after each use to prevent premature wear. Use a soft brush and mild soap to clean the uppers, avoiding harsh chemicals.

Tip 6: Address Damage Promptly: Repair minor tears or abrasions immediately to prevent further deterioration. Consider using specialized adhesives designed for footwear repair.

Tip 7: Rotate Footwear: If skateboarding frequently, rotate between multiple pairs of shoes to allow each pair to air out and prolong its lifespan. This reduces stress on individual pairs.

Adhering to these guidelines will contribute to improved skateboarding performance, enhanced safety, and increased durability of skate-specific footwear. The following section will provide a conclusion summarizing the key aspects discussed.

The final part of the article will recap the points mentioned before.

1. Sole grip

Sole grip in skateboarding footwear is a critical determinant of performance, affecting board control and trick execution. The interaction between the sole’s material and the skateboard’s grip tape directly influences the skater’s ability to maintain contact with the board, particularly during complex maneuvers. Insufficient sole grip can lead to slippage, causing missed tricks and potential injuries. Therefore, the selection of materials and tread patterns for the sole construction is paramount in footwear designed for skateboarding.

The material commonly employed for soles in skateboarding footwear is vulcanized rubber, selected for its high coefficient of friction and durability. The vulcanization process enhances the rubber’s strength and elasticity, providing a reliable grip surface. Tread patterns further augment grip by creating edges that interlock with the skateboard’s grip tape. For instance, waffle patterns are frequently used due to their effectiveness in providing multi-directional grip. A real-world example would be a skater consistently landing tricks on a new board due to the superior sole adhesion of their chosen footwear.

Understanding the relationship between sole grip and footwear efficacy allows skaters to make informed decisions about equipment selection. Challenges in sole grip can stem from wear and tear, contamination with dirt or debris, or the use of unsuitable footwear. Recognizing these factors enables skaters to mitigate grip-related issues through regular cleaning, shoe replacement, or the application of grip-enhancing products. The significance of sole grip extends beyond individual performance, impacting safety and the overall progression of skills within the skateboarding discipline.

2. Abrasion resistance

Abrasion resistance, a crucial attribute of specialized skateboarding footwear, directly influences the longevity and performance of the equipment. Skateboarding activities inherently subject footwear to significant frictional forces from contact with abrasive surfaces such as asphalt, concrete, and grip tape. Inadequate abrasion resistance leads to rapid deterioration of the shoe’s upper material, compromising structural integrity and necessitating frequent replacements. This, in turn, impacts the skater’s performance, comfort, and financial expenditure.

The selection of materials with high abrasion resistance is therefore paramount in the design and manufacturing of skate-specific shoes. Suede leather and reinforced synthetic fabrics are commonly employed due to their inherent ability to withstand friction. Reinforcements, such as additional layers of material or specialized stitching patterns in high-wear areas (e.g., the toe box and ollie patch), further augment abrasion resistance. For instance, a skater performing ollies repeatedly stresses the outer edge of the shoe. Footwear with enhanced reinforcement in this area will exhibit greater resistance to wear and tear, extending the shoe’s usable lifespan. The absence of adequate abrasion resistance inevitably results in compromised footwear integrity, affecting safety and performance.

Understanding the relationship between abrasion resistance and footwear longevity allows skaters to make informed purchasing decisions and implement preventative measures to prolong the lifespan of their equipment. Regularly cleaning footwear to remove abrasive particles, applying protective coatings, and employing appropriate skateboarding techniques can mitigate the impact of friction. The selection of footwear exhibiting superior abrasion resistance is a critical investment for serious skateboarders, balancing performance requirements with cost-effectiveness over the long term. Footwear that don’t have good material will fail in abrasive resistant, making the user have bad experience.

3. Impact cushioning

Impact cushioning, a critical element in skateboarding footwear, directly mitigates the physical stresses experienced during high-impact activities. This feature is essential for minimizing the risk of injury and enhancing overall performance in skateboarding.

- Role of Midsole Materials

The midsole, situated between the insole and outsole, serves as the primary source of impact cushioning. Materials such as ethylene-vinyl acetate (EVA) and polyurethane (PU) are commonly employed due to their shock-absorbing properties. EVA offers lightweight cushioning, while PU provides greater durability and support. The selection of midsole material significantly influences the shoe’s ability to attenuate impact forces during landings. For example, a skater performing a large drop will experience substantial force upon landing; a shoe with an inadequate midsole will transmit more of this force to the skater’s joints, increasing the risk of injury.

- Influence of Insole Design

The insole, positioned directly beneath the foot, contributes to impact cushioning and overall comfort. Insoles incorporating gel or foam padding further enhance shock absorption. Ortholite insoles, known for their antimicrobial properties and breathability, are frequently used in skateboarding footwear to improve comfort and reduce moisture build-up. An example of the insole’s importance is that a skater landing primo (landing on the edge of the board) would experience intense pressure on the insole; a well-designed insole dissipates this pressure, protecting the foot from bruising and discomfort.

- Relationship with Outsole Construction

The outsole, the shoe’s outermost layer, also plays a role in impact cushioning by providing a stable platform and absorbing initial impact forces. Thick rubber outsoles, often featuring intricate tread patterns for grip, contribute to overall shock absorption. The durometer (hardness) of the rubber used in the outsole influences its cushioning properties; softer rubber provides greater cushioning but may wear down more quickly. As an illustration, a skater performing a powerslide relies on the outsole to absorb impact and distribute force; a durable outsole with good cushioning properties minimizes the risk of injury.

- Effect on Joint Protection

Effective impact cushioning protects the skater’s joints, including ankles, knees, and hips, from repetitive stress and high-impact forces. Insufficient cushioning increases the risk of injuries such as ankle sprains, knee pain, and stress fractures. Skateboarding footwear incorporating advanced cushioning technologies significantly reduces the likelihood of these injuries, allowing skaters to perform at their best while minimizing the risk of physical harm. The correlation between joint and impact cushioning can be describe of a skater doing a kickflip, good cushioning will give more protection to ankle.

These components collectively contribute to the impact cushioning properties of footwear designed for skateboarding. The selection of appropriate materials and construction techniques is paramount in ensuring that these specialized shoes effectively mitigate the forces experienced during skateboarding activities, providing essential protection and enhancing overall performance. The dg skate shoes will give good impact cushioning to the users.

4. Ankle support

Ankle support in skateboarding footwear directly affects stability and injury prevention. Specialized designs incorporate features aimed at minimizing the risk of ankle sprains and strains during high-impact maneuvers.

- Collar Height and Padding

The height of the shoe collar and the amount of padding surrounding the ankle significantly influence support. Higher collars provide greater stability, while padding cushions the ankle against impacts. For instance, a skater landing awkwardly may rely on a high, padded collar to prevent excessive ankle roll. The construction of the collar directly affects the shoe’s ability to provide lateral stability, mitigating the risk of injury during landings and board control.

- Internal Heel Counters

Internal heel counters, typically constructed from rigid materials such as thermoplastic polyurethane (TPU), reinforce the heel cup and prevent excessive pronation or supination of the foot. These counters maintain the foot’s alignment within the shoe, improving stability and reducing stress on the ankle joint. An example is a skater with a tendency to overpronate; a shoe with a robust heel counter can help correct this imbalance, reducing the risk of ankle and knee injuries. Thus, the heel counter’s material and design profoundly impact ankle support.

- Lacing Systems and Midfoot Support

The lacing system and midfoot support work in tandem to secure the foot within the shoe, preventing slippage and enhancing ankle stability. Lacing systems that extend further down the foot provide a more customized and secure fit. Internal straps or cages can also augment midfoot support, further minimizing foot movement within the shoe. As an illustration, a skater performing a trick that requires quick foot movements depends on a secure lacing system to maintain foot placement, preventing instability and potential ankle injuries.

- Material Stiffness and Flexibility

The overall stiffness and flexibility of the shoe’s upper material influence ankle support. Stiffer materials provide greater stability but may restrict movement, while more flexible materials allow for a greater range of motion but offer less support. A balance between these two properties is essential for optimal performance and injury prevention. For example, a skater performing technical tricks requires flexibility for board feel but also needs sufficient ankle support to prevent injuries. This underscores the trade-offs inherent in material selection for ankle support.

These features collectively define the ankle support characteristics of skateboarding footwear. Designs incorporating a combination of high collars, padded interiors, rigid heel counters, secure lacing systems, and balanced material stiffness contribute to superior ankle stability and injury prevention, supporting the skater’s performance. dg skate shoes must be have a good ankle support so the skater won’t have a injuries.

5. Board feel

Board feel, in the context of skateboarding footwear, denotes the tactile connection between the skater’s foot and the skateboard. This connection is mediated by the shoe’s sole construction, influencing the skater’s ability to perceive the board’s position and orientation. A heightened sense of board feel allows for more precise control and execution of tricks. Specialized skateboarding footwear, including “dg skate shoes,” prioritizes sole designs that maximize this tactile feedback, enabling skaters to make minute adjustments in their weight distribution and foot placement.

The construction of the sole directly impacts board feel. Thinner soles, typically made of vulcanized rubber, provide a more direct connection compared to thicker, cupsole constructions. The durometer, or hardness, of the rubber also affects board feel; softer rubber enhances grip and tactile sensitivity but may wear down more quickly. For example, a skater performing a kickflip relies on precise foot placement on the board’s concave. Footwear with enhanced board feel allows the skater to sense the edge of the board and initiate the flip with greater accuracy. The absence of adequate board feel can lead to missed tricks and reduced overall control.

The emphasis on board feel in the design of “dg skate shoes” highlights the importance of tactile feedback in skateboarding performance. By prioritizing sole construction that maximizes this connection, these shoes enable skaters to achieve greater control and precision. Challenges in achieving optimal board feel may include the trade-off between durability and sensitivity, as well as individual skater preferences. Understanding the practical significance of board feel allows skaters to select footwear that aligns with their performance goals and enhances their overall skateboarding experience. This understanding supports skill development and performance, leading to the skater feel more better.

6. Material durability

Material durability is a paramount consideration in the design and performance of skateboarding footwear. “dg skate shoes,” like other specialized skate shoes, are subjected to extreme conditions, necessitating the use of materials that can withstand significant abrasion, impact, and stress. The selection and construction of these materials directly influence the lifespan, safety, and overall value of the footwear.

- Abrasion Resistance of Uppers

The upper portion of skate shoes experiences constant friction against the skateboard’s grip tape and other surfaces. Materials such as suede, leather, and reinforced synthetics are chosen for their abrasion-resistant properties. For example, the ollie area of the shoe, which is repeatedly subjected to friction during ollies, often features additional layers of material or specialized stitching to enhance durability. The quality of these materials directly impacts how long the shoes can withstand the wear and tear of skateboarding before requiring replacement.

- Sole Composition and Bonding

The sole of a skate shoe must provide grip and absorb impact while withstanding constant pressure and abrasion. Vulcanized rubber is commonly used due to its durability and flexibility. The bonding process between the sole and the upper is equally critical; a weak bond can lead to separation, rendering the shoe unusable. An example of this is a sole delaminating after only a few weeks of use due to inadequate adhesive or poor construction techniques. Therefore, the composition and bonding of the sole are vital to the overall durability of skate shoes.

- Reinforcement of Stress Points

Specific areas of skate shoes, such as the toe cap and heel, are prone to high stress and impact. Reinforcements in these areas, such as double stitching, metal eyelets, and additional layers of material, are incorporated to enhance durability. For instance, a skater landing heavily on their heel will place significant stress on the heel counter; a well-reinforced heel counter will prevent deformation and extend the life of the shoe. The strategic reinforcement of stress points is essential for ensuring the longevity of “dg skate shoes.”

- Impact of Construction Techniques

The method of construction significantly influences the overall durability of skate shoes. Double or triple stitching, reinforced seams, and the use of durable threads contribute to a stronger and more resilient shoe. Poor construction techniques, such as single stitching or the use of low-quality threads, can lead to premature failure, even if the materials themselves are of high quality. As an example, a shoe with poorly stitched seams may fall apart quickly under the stress of skateboarding, regardless of the quality of the suede or rubber used. Therefore, construction techniques are as important as the materials themselves in determining the durability of “dg skate shoes.”

The aspects mentioned influence the ability of the skater performing the skill and makes the user not easy to replace the shoes, makes the shoes more economical and sustainable. They are the most valuable aspect on “dg skate shoes”.

7. Stitching Reinforcement

Stitching reinforcement is a critical element in the design of durable skateboarding footwear, directly influencing the lifespan and performance of “dg skate shoes.” Given the abrasive and high-impact nature of skateboarding, standard stitching methods are often inadequate to withstand the stresses placed on the shoes. Reinforced stitching addresses this deficiency by providing added strength and resilience to critical seams and stress points.

- Reinforcement at High-Stress Areas

High-stress areas, such as the ollie patch, toe cap, and heel, are particularly vulnerable to wear and tear. “dg skate shoes” often incorporate reinforced stitching at these locations to prevent premature failure. This may involve using thicker threads, multiple rows of stitching, or specialized stitching patterns. For example, triple stitching along the ollie patch provides enhanced resistance against abrasion from the skateboard’s grip tape, significantly extending the shoe’s lifespan. Without this reinforcement, these areas would quickly degrade, compromising the shoe’s structural integrity.

- Use of High-Tensile Threads

The type of thread used in stitching directly affects its strength and durability. High-tensile threads, typically made from nylon or polyester, offer superior resistance to breaking and abrasion compared to standard cotton threads. “dg skate shoes” utilize these high-tensile threads to ensure that seams remain intact under stress. As an example, a skater performing a kickflip places significant stress on the side seams of the shoe. High-tensile threads prevent these seams from tearing, maintaining the shoe’s structural integrity and preventing discomfort or injury.

- Stitch Density and Pattern

The density of stitches per inch and the specific stitching pattern employed also contribute to reinforcement. A higher stitch density provides a greater number of anchor points, distributing stress more evenly and reducing the likelihood of seam failure. Specialized stitching patterns, such as zigzag or cross-stitching, offer additional strength and flexibility. “dg skate shoes” strategically use stitch density and patterns to optimize reinforcement. For instance, a zigzag stitch along the toe cap provides flexibility while maintaining strength, preventing the cap from tearing away from the sole during high-impact landings.

- Integration with Material Selection

Stitching reinforcement is most effective when integrated with appropriate material selection. Durable materials like suede or reinforced canvas, combined with reinforced stitching, create a synergistic effect that maximizes the lifespan of “dg skate shoes.” The thread can prevent the material from being pulled apart by the skater activity. For example, a suede upper with triple-stitched seams provides a robust and long-lasting combination that can withstand the rigors of skateboarding. The interplay between material and stitching is crucial for achieving optimal durability.

The integration of these stitching reinforcement techniques is essential for ensuring the durability and performance of “dg skate shoes.” By addressing the specific stresses encountered during skateboarding, reinforced stitching contributes to a longer lifespan, improved safety, and enhanced overall value for the skater.

Frequently Asked Questions about dg skate shoes

This section addresses common inquiries regarding the selection, maintenance, and performance characteristics of footwear designed for skateboarding, with a particular focus on aspects relevant to “dg skate shoes.”

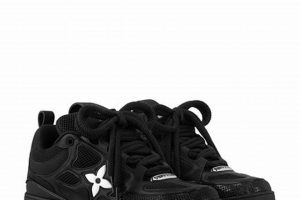

Question 1: What distinguishes dg skate shoes from standard athletic footwear?

Footwear designed for skateboarding incorporates specialized features absent in standard athletic shoes. These include reinforced stitching, durable outsoles for enhanced grip, and specific cushioning technologies to absorb impact during landings. The “dg skate shoes” are engineered to withstand the abrasive conditions and high-stress maneuvers inherent in skateboarding.

Question 2: How does sole construction impact the performance of dg skate shoes?

Sole construction is a critical determinant of board feel, grip, and durability. Vulcanized soles provide optimal board feel and flexibility, while cupsole constructions offer greater impact protection. The tread pattern influences grip on the skateboard. “dg skate shoes” typically feature sole constructions tailored to balance these performance attributes.

Question 3: What materials are commonly used in dg skate shoes and why?

Materials used in “dg skate shoes” are selected for their abrasion resistance, durability, and support. Suede and leather uppers provide resistance to wear and tear, while reinforced synthetics offer enhanced durability and breathability. High-tensile threads are used for stitching to prevent seam failure under stress.

Question 4: How should dg skate shoes be maintained to prolong their lifespan?

Proper maintenance extends the lifespan of “dg skate shoes.” Regular cleaning to remove dirt and debris is essential. Minor repairs to tears or abrasions should be addressed promptly. Rotating between multiple pairs of shoes allows each pair to air out and reduces stress on individual shoes. Avoid exposing the shoes to extreme temperatures or harsh chemicals.

Question 5: How important is ankle support in dg skate shoes?

Ankle support is a significant factor in preventing injuries. “dg skate shoes” may feature padded collars, high-top designs, and internal heel counters to enhance ankle stability and reduce the risk of sprains or strains. The level of ankle support should align with the skater’s individual needs and skateboarding style.

Question 6: Can dg skate shoes be used for activities other than skateboarding?

While “dg skate shoes” are designed specifically for skateboarding, they can be worn for other activities. However, their specialized construction may not be optimal for all athletic pursuits. Their durability and support make them suitable for casual wear or activities requiring similar footwear characteristics.

These FAQs provide a foundational understanding of the key aspects of “dg skate shoes,” aiding in informed decision-making regarding their purchase and use. Understanding these factors contributes to enhanced skateboarding performance and equipment longevity.

The next section will summarize the article.

Conclusion

The preceding analysis has underscored the critical attributes of specialized skateboarding footwear, specifically focusing on design elements pertinent to “dg skate shoes.” The emphasis has been placed on sole grip, abrasion resistance, impact cushioning, ankle support, board feel, material durability, and stitching reinforcement. Each attribute contributes significantly to the overall performance, safety, and longevity of skate-specific footwear, directly impacting the skater’s ability to execute maneuvers and minimize the risk of injury.

Ultimately, the selection of appropriate skateboarding footwear represents a crucial investment in performance and personal safety. A comprehensive understanding of the design considerations outlined herein empowers skaters to make informed decisions, ensuring optimal equipment selection for their specific needs and skateboarding style. Continued innovation in material science and construction techniques promises further advancements in specialized skateboarding footwear, driving progress within the discipline.