Footwear designed for skateboarding manufactured by Puma constitutes a specialized category within the broader athletic shoe market. These articles of apparel are engineered to withstand the rigors of skateboarding, incorporating features such as durable outsoles, reinforced uppers, and cushioned insoles to provide both protection and board feel.

The significance of this type of footwear lies in its ability to enhance performance and safety for skateboarders. Durable construction extends the lifespan of the product, reducing the frequency of replacement. Features like enhanced grip and impact absorption contribute to improved control and reduced risk of injury. Puma’s entry into this market segment represents an expansion of their athletic apparel offerings, potentially reaching a new demographic of consumers.

The following sections will delve into specific design elements, material choices, technological innovations, and market positioning strategies employed in the creation and distribution of skateboarding footwear by Puma. Furthermore, the analysis will consider the competitive landscape and the brand’s efforts to establish a strong presence within this niche market.

Guidance on Selection and Maintenance

Selecting appropriate footwear for skateboarding requires careful consideration. The following guidance provides essential information for consumers aiming to optimize performance and longevity when engaging with articles designed for skateboarding.

Tip 1: Prioritize Durability: Examine the construction materials. Reinforced stitching and robust outsoles are indicative of enhanced resilience against the abrasive nature of skateboarding.

Tip 2: Assess Outsole Grip: Evaluate the outsole pattern and material. A textured pattern composed of a high-friction rubber compound provides superior board adhesion.

Tip 3: Evaluate Ankle Support: Consider the level of ankle support offered. Higher-cut designs offer increased stability and protection, particularly beneficial for beginners or those attempting advanced maneuvers.

Tip 4: Inspect Impact Absorption: Investigate the insole and midsole construction. Adequate cushioning is crucial for mitigating impact forces generated during landings and tricks.

Tip 5: Confirm Proper Fit: Ensure an accurate and snug fit. Excessive movement within the shoe can lead to blisters and reduced control.

Tip 6: Regular Cleaning: Implement a consistent cleaning regimen. Removing dirt and debris prevents premature wear and maintains the aesthetic appeal.

Tip 7: Rotate Usage: If possible, alternate between multiple pairs. Allowing each pair to rest and dry prolongs its lifespan.

Adhering to these guidelines facilitates informed purchasing decisions and promotes responsible maintenance practices, ultimately maximizing the value and performance of skateboarding-specific footwear.

The subsequent section will explore the technology implemented and a conclusion of “puma skate shoe”.

1. Durability

Within the context of skateboarding footwear, durability represents a paramount attribute. The abrasive nature of skateboarding subjects shoes to extreme wear and tear, necessitating robust construction and resilient materials to withstand the rigors of the activity. For Puma’s skateboarding line, the emphasis on durability translates directly into product longevity and performance.

- Material Selection

Puma employs specific materials known for their abrasion resistance. Suede, leather, and reinforced canvas are commonly utilized in the uppers to mitigate the effects of grip tape contact. The choice of high-density rubber for the outsoles further contributes to the overall lifespan, as it is more resistant to wear than conventional rubber compounds. For example, double-stitching on high-stress areas like the toe cap reinforces the construction and prevents premature separation of components.

- Construction Techniques

The methods used to assemble the shoe significantly impact its structural integrity. Vulcanized construction, where the outsole is chemically bonded to the upper, is frequently employed for its strength and flexibility. Stitching patterns, such as double or triple stitching, reinforce seams and prevent tearing. An example includes the use of a reinforced heel counter to provide added stability and prevent breakdown in this vulnerable area.

- Reinforcement Strategies

Specific areas of the shoe prone to high wear receive targeted reinforcement. Additional layers of material are strategically placed to provide extra protection. Rubber toe caps, for instance, protect the front of the shoe from abrasion during ollies and other tricks. Metal eyelets reinforce the lacing system, preventing premature wear and tear from repeated tightening. Reinforcement can significantly extend the life of the shoe.

- Quality Control

Rigorous quality control processes during manufacturing ensure consistent product quality. Testing procedures evaluate the tensile strength of materials, the adhesion of components, and the overall structural integrity of the shoe. This process reduces the likelihood of premature failure and enhances consumer confidence in the product’s durability. These tests prevent the release of subpar products into the marketplace.

These facets of durability are interwoven in Puma’s skateboarding footwear, aiming to create products that endure the demands of skateboarding while maintaining performance characteristics. The combination of material selection, construction techniques, reinforcement strategies, and rigorous quality control contribute to a more durable and reliable shoe for skateboarders.

2. Grip

Grip, in the context of Puma skateboarding footwear, constitutes a critical performance parameter directly impacting board control and skater safety. The coefficient of friction between the shoe’s outsole and the skateboard’s grip tape dictates the level of adhesion achievable during maneuvers. Insufficient grip leads to slippage, compromising trick execution and increasing the risk of falls. Conversely, optimal grip provides enhanced stability, enabling precise control and facilitating advanced techniques. The selection of rubber compounds and the design of outsole patterns are pivotal in achieving the desired level of grip. For instance, a skater attempting an ollie relies on the shoe’s ability to maintain contact with the board throughout the pop and subsequent airtime. Without adequate grip, the feet may detach from the board, leading to a failed attempt and potential injury.

Puma engineers employ various strategies to optimize grip performance in skateboarding shoes. Specialized rubber compounds, often incorporating proprietary formulations, are selected for their high coefficient of friction. Outsole patterns are designed with intricate tread patterns, featuring micro-grooves and directional sipes, to maximize surface contact and channel away debris that could reduce adhesion. Furthermore, the durometer (hardness) of the rubber is carefully calibrated to balance grip with durability. Softer rubber provides superior grip but tends to wear more quickly, while harder rubber offers increased longevity but may compromise traction. An example involves the development of a specific outsole pattern designed to mimic the micro-texture of sandpaper, effectively interlocking with the skateboard’s grip tape and minimizing slippage.

In conclusion, grip stands as a fundamental attribute of Puma’s skateboarding footwear. The interaction between rubber composition, outsole design, and skater technique determines the efficacy of grip. Challenges remain in balancing grip performance with outsole durability, requiring continuous innovation in material science and pattern engineering. The successful integration of these factors contributes to enhanced skater performance, improved safety, and the overall appeal of the brand within the skateboarding community.

3. Support

Skeletal and muscular support within the human foot and ankle complex becomes paramount when considering the biomechanical stresses inherent in skateboarding. Footwear designed for this activity must provide adequate structural reinforcement to mitigate the risk of injury and enhance performance. Puma skate shoes integrate support mechanisms to address specific needs arising from repeated impact, lateral movement, and the demand for precise board control. Inadequate support can lead to sprains, strains, and chronic conditions resulting from repetitive stress. For instance, a skater repeatedly landing ollies places significant stress on the ankle joint; properly designed footwear can limit excessive pronation and supination, reducing the likelihood of injury. The design of a skate shoe to support such activity demonstrates the importance and practical significance of the product.

Puma integrates various structural elements to deliver support in its skateboarding footwear. High-cut designs offer increased ankle stabilization, limiting range of motion and preventing excessive inversion or eversion. Reinforced heel counters maintain the shoe’s shape and prevent heel slippage, contributing to a more secure fit. Internal supports, often constructed from thermoplastic polyurethane (TPU), provide additional rigidity in key areas, such as the midfoot, enhancing torsional stability. Furthermore, cushioned insoles offer arch support, which can improve biomechanical alignment and reduce fatigue during prolonged skateboarding sessions. For example, a skater attempting a complex trick requiring precise foot placement benefits from the enhanced stability provided by these supportive features, resulting in increased confidence and a reduced risk of missteps.

In summary, the level of support provided by Puma skate shoes is a crucial factor influencing both safety and performance. Design elements such as high-cut profiles, reinforced heel counters, and internal support structures work in concert to mitigate the risks associated with skateboarding’s inherent biomechanical stresses. Ongoing innovation in materials and design will continue to improve the level of support offered, further enhancing the overall skateboarding experience. Considerations for custom orthotics can also be integrated for a personalized level of support. Challenges exist in balancing support with flexibility and board feel, requiring meticulous design and material selection.

4. Cushioning

Cushioning in Puma skateboarding footwear represents a critical design element that mitigates impact forces generated during landings and tricks. Its presence serves to enhance comfort, reduce fatigue, and minimize the risk of injury, particularly to joints and connective tissues. The type and placement of cushioning materials directly influence the performance and long-term health of the skater.

- Impact Absorption Capabilities

The primary role of cushioning is to absorb kinetic energy during impact. This is achieved through the deformation of materials within the shoe’s midsole and insole. For instance, landing an ollie generates significant force that travels through the skater’s feet and ankles. Effective cushioning dissipates this energy, reducing the stress on these joints. Materials such as ethylene-vinyl acetate (EVA) and polyurethane (PU) are commonly employed for their shock-absorbing properties. The efficiency of impact absorption directly correlates with the reduction of fatigue and potential for injury.

- Material Density and Placement

The density of cushioning materials and their strategic placement are critical factors in optimizing performance. Higher-density materials offer greater impact protection but can reduce board feel. Conversely, lower-density materials provide enhanced board feel but may compromise impact absorption. Puma often employs a multi-density approach, placing denser materials in high-impact zones, such as the heel, and lower-density materials in areas requiring greater flexibility. For example, the forefoot may utilize a thinner layer of cushioning to maintain board feel, while the heel incorporates a thicker, higher-density material to protect against heel bruising during landings.

- Energy Return Properties

Cushioning not only absorbs impact but can also contribute to energy return, enhancing performance. Certain materials, such as specialized foams, compress upon impact and then rebound, providing a slight boost during push-offs and transitions. This energy return can reduce fatigue and improve overall efficiency during skateboarding. For instance, a skater performing a kickflip may benefit from the energy return provided by the cushioning in their shoes, facilitating the pop and flick required for the trick.

- Long-Term Comfort and Support

In addition to impact absorption, cushioning also contributes to long-term comfort and support. Well-cushioned insoles can provide arch support, improving biomechanical alignment and reducing fatigue during prolonged skateboarding sessions. The cushioning also molds to the shape of the foot over time, providing a customized fit and enhanced comfort. This is especially important for skaters who spend hours on their boards, as consistent comfort can improve focus and reduce the likelihood of overuse injuries.

The interplay of impact absorption, material density, energy return, and long-term comfort defines the effectiveness of cushioning in Puma’s skateboarding footwear. Continuous advancements in material science and design contribute to improved cushioning systems, enhancing performance, safety, and overall enjoyment for skaters. The careful calibration of these factors allows skaters to push their limits with greater confidence and reduced risk.

5. Style

Style, within the context of Puma skate shoes, represents more than mere aesthetics; it embodies a carefully considered fusion of functionality, brand identity, and the cultural norms of skateboarding. The visual design of a skateboarding shoe directly impacts its perceived value and acceptance within the skateboarding community. Puma’s designs must balance practicalitymeeting the demands of skateboardingwith aesthetic appeal, aligning with current trends and the brand’s overall image. For example, a shoe featuring durable suede uppers, reinforced stitching, and a low-profile silhouette may appeal to skateboarders seeking performance-oriented footwear. However, the integration of unique color palettes, graphic elements, or subtle branding details is vital to establish a distinct stylistic identity.

The stylistic choices made in the design of Puma skate shoes reflect a symbiotic relationship between brand recognition and consumer preferences within the skateboarding subculture. A specific colorway, a recognizable logo placement, or the incorporation of design cues borrowed from classic Puma silhouettes can contribute to the shoe’s desirability and market success. For instance, a collaboration with a prominent skateboarder or artist can lend credibility and influence the shoe’s design, further enhancing its stylistic appeal. The practical application of this understanding lies in Puma’s ability to tailor its designs to resonate with its target audience, fostering brand loyalty and driving sales.

In summary, style is an integral component of Puma skate shoes, influencing both consumer perception and product success. The balancing act between performance functionality and aesthetic appeal demands meticulous attention to detail and a deep understanding of skateboarding culture. By strategically incorporating design elements that reflect both the brand’s identity and the preferences of its target demographic, Puma can establish a strong stylistic presence within the competitive skateboarding footwear market. Challenges remain in maintaining authenticity and avoiding the pitfalls of trend-chasing, requiring continuous innovation and a genuine connection to the skateboarding community.

6. Materials

The selection of materials for Puma skate shoes represents a critical determinant of performance, durability, and overall product quality. Each component material contributes specific properties that impact the shoe’s ability to withstand the demands of skateboarding while providing comfort and support. The strategic application of diverse materials is, therefore, essential to the design and manufacture of these specialized footwear.

- Upper Construction: Suede and Leather

Suede and leather are frequently employed in the upper construction of Puma skate shoes due to their inherent abrasion resistance and ability to conform to the foot over time. Suede offers a balance of durability and flexibility, while leather provides enhanced structure and protection. The choice between these materials often depends on the intended use and design aesthetic of the shoe. Reinforced stitching and strategically placed overlays further enhance the upper’s resistance to wear and tear, particularly in areas prone to abrasion from grip tape contact. For example, a heavily reinforced suede toe cap is common in skate shoes designed for technical street skating.

- Outsole Composition: Rubber Compounds

The outsole material dictates the shoe’s grip, durability, and board feel. High-abrasion rubber compounds are essential to withstand the constant friction and impact associated with skateboarding. The specific formulation of the rubber compound influences its coefficient of friction, determining the level of adhesion between the shoe and the skateboard. A harder rubber compound offers increased durability but may compromise grip, while a softer compound provides superior grip but may wear more quickly. Puma often utilizes proprietary rubber formulations to achieve an optimal balance of these characteristics. Furthermore, the outsole pattern influences grip performance, with varied tread designs designed to enhance traction in different conditions. A textured, multi-directional tread pattern is common in skate shoes to maximize surface contact and channel away debris.

- Midsole Cushioning: EVA and Polyurethane

The midsole provides cushioning and support, absorbing impact forces during landings and tricks. Ethylene-vinyl acetate (EVA) and polyurethane (PU) are commonly used midsole materials, each offering distinct properties. EVA provides lightweight cushioning and flexibility, while PU offers greater durability and energy return. The density and thickness of the midsole material influence the level of impact protection and board feel. A thicker, higher-density midsole provides greater impact absorption but may reduce board feel, while a thinner, lower-density midsole offers enhanced board feel but may compromise impact protection. Puma often employs a combination of these materials to achieve an optimal balance of cushioning and board feel. For example, a dual-density midsole may feature a higher-density PU heel for impact protection and a lower-density EVA forefoot for enhanced board feel.

- Internal Components: Linings and Reinforcements

Internal components such as linings and reinforcements contribute to the shoe’s comfort, fit, and structural integrity. Moisture-wicking linings enhance comfort and prevent slippage, while reinforced heel counters provide stability and prevent heel slippage. Internal reinforcements, such as thermoplastic polyurethane (TPU) shanks, enhance torsional stability and prevent the shoe from twisting excessively during lateral movements. These internal components contribute to the overall comfort, fit, and performance of the shoe. For example, a padded collar and tongue enhance comfort and prevent irritation, while a reinforced heel counter provides stability and support.

The interplay between these material choices defines the overall performance and characteristics of Puma skate shoes. The successful integration of durable uppers, high-grip outsoles, cushioning midsoles, and supportive internal components results in a product that meets the specific needs and demands of skateboarders. Ongoing innovation in material science continues to drive advancements in Puma skate shoe design, enhancing performance, durability, and comfort.

7. Innovation

Innovation represents a crucial driver in the evolution of skateboarding footwear. Puma’s efforts in this arena are directly linked to improvements in performance, safety, and sustainability within the specialized realm of skateboarding. This exploration will detail specific innovations that impact the design and functionality of Puma skate shoes.

- Advanced Material Composites

The integration of novel material composites enhances durability and performance. Proprietary rubber compounds engineered for superior grip, abrasion resistance, and board feel exemplify this innovation. Synthetic fabrics designed to offer increased breathability, reduced weight, and enhanced structural support are also integral. These advances allow for improved control, reduced wear, and enhanced comfort for the skater. For example, the development of a rubber compound with increased rebound properties provides enhanced board feel and responsiveness.

- Ergonomic Design and Biomechanics

Innovations in ergonomic design and biomechanics contribute to optimized fit, support, and impact absorption. Anatomically shaped insoles designed to provide arch support, reduce fatigue, and improve foot alignment represent one aspect. The implementation of cushioning systems engineered to dissipate impact forces and minimize stress on joints exemplifies another. The objective is to improve comfort, reduce the risk of injury, and enhance overall skating performance. An example includes the strategic placement of high-density foam in areas prone to high impact, such as the heel and forefoot.

- Sustainable Manufacturing Practices

The adoption of sustainable manufacturing practices reduces environmental impact. The utilization of recycled materials in upper construction, outsole production, and packaging exemplifies this. The implementation of water-based adhesives and low-VOC (volatile organic compound) finishes minimizes the release of harmful chemicals. The goal is to reduce the environmental footprint of skateboarding footwear production. Examples include the incorporation of recycled rubber in outsoles and the use of organic cotton in linings.

- Digital Design and Rapid Prototyping

The application of digital design tools and rapid prototyping techniques accelerates product development and enables more precise design optimization. Computer-aided design (CAD) software allows for the creation of complex three-dimensional models, facilitating the precise placement of features and the optimization of structural integrity. Three-dimensional printing technologies enable the rapid creation of prototypes for testing and refinement. The purpose is to shorten development cycles, improve design accuracy, and facilitate the creation of innovative features. An example includes the use of 3D-printed molds to test the fit and performance of new insole designs.

These facets of innovation converge to shape the future of Puma skate shoes. The ongoing pursuit of advancements in materials, design, manufacturing, and testing contributes to enhanced performance, improved safety, and reduced environmental impact. The integration of these innovations is critical to maintaining competitiveness and meeting the evolving demands of the skateboarding community. The convergence of technology, sustainability, and skater input is reshaping the landscape of skateboarding footwear.

Frequently Asked Questions

This section addresses common inquiries regarding Puma skate shoes, providing factual information to assist consumers in making informed decisions.

Question 1: What differentiates a Puma skate shoe from a standard athletic shoe?

Puma skate shoes are specifically engineered to withstand the rigors of skateboarding. Key distinctions include reinforced construction, durable outsoles designed for grip, and specialized cushioning systems to absorb impact forces. Standard athletic shoes typically lack these features, rendering them less suitable for skateboarding.

Question 2: How does the outsole of a Puma skate shoe enhance performance?

The outsole utilizes specialized rubber compounds and tread patterns to maximize grip and board feel. The specific formulation of the rubber influences its coefficient of friction, determining the level of adhesion between the shoe and the skateboard. Tread patterns are designed to enhance surface contact and channel away debris that could reduce traction. This combination contributes to enhanced board control and stability.

Question 3: What materials are commonly used in the construction of Puma skate shoe uppers, and why?

Suede and leather are frequently employed due to their abrasion resistance and ability to conform to the foot. These materials provide a balance of durability, flexibility, and support. Reinforced stitching and strategically placed overlays further enhance the upper’s resistance to wear and tear, particularly in high-stress areas.

Question 4: How does Puma address impact protection in its skate shoe designs?

Puma integrates cushioning systems designed to absorb kinetic energy during landings and tricks. Materials such as ethylene-vinyl acetate (EVA) and polyurethane (PU) are commonly used in the midsole, providing shock absorption and reducing stress on joints. The density and placement of these materials are strategically optimized to balance impact protection with board feel.

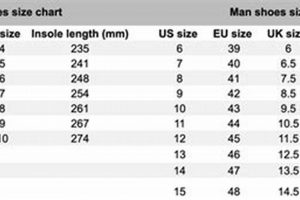

Question 5: What factors should be considered when selecting the appropriate size and fit of a Puma skate shoe?

Proper fit is essential for both performance and comfort. Ensure an adequate amount of toe room to prevent discomfort and potential injury. The shoe should provide a secure fit around the heel and midfoot, preventing slippage during activity. Consult sizing charts and reviews to determine the appropriate size, as variations may exist between different models and brands.

Question 6: How can the lifespan of Puma skate shoes be extended?

Implementing proper maintenance practices can significantly extend the lifespan. Regularly cleaning the shoes to remove dirt and debris is essential. Avoiding excessive exposure to moisture and extreme temperatures can prevent material degradation. Reinforcing high-wear areas with adhesive patches or protective coatings can provide additional protection. Rotating between multiple pairs of shoes allows each pair to rest and recover, prolonging their overall lifespan.

These frequently asked questions provide a foundation for understanding the design considerations and performance characteristics of Puma skate shoes. Informed decision-making enhances both safety and satisfaction.

The following section will explore a conclusion of “Puma Skate Shoe”.

Conclusion

This exposition has provided a detailed examination of footwear designed for skateboarding and manufactured by Puma. The analysis encompassed key design features such as durability, grip, support, cushioning, and style, alongside the materials and innovative technologies employed in their creation. A rigorous assessment of these elements reveals the complex interplay between engineering principles, skateboarding culture, and brand identity that defines these specialized products.

The continued evolution of Puma skate shoes hinges on a commitment to innovation, sustainable practices, and responsiveness to the needs of the skateboarding community. Future progress in material science and biomechanical design will further refine the performance and safety characteristics of these products. Ongoing engagement with skaters and a dedication to quality are crucial for maintaining relevance and achieving sustained success in this dynamic market.

![Top Rated: Best Skate Shoe Company Guide [2024] Learn to Surf & Skate: A Beginner's Step-by-Step Guide Top Rated: Best Skate Shoe Company Guide [2024] | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/02/th-230-300x200.jpg)