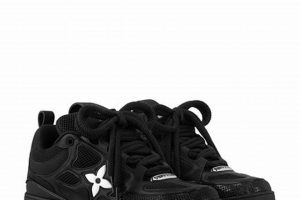

Specialized footwear designed for enhanced grip and durability on inclined surfaces during construction tasks is a type of footwear often adapted from the skateboarding world. These shoes typically feature a flat, vulcanized rubber sole with a high coefficient of friction. For example, a roofer might choose this footwear over traditional work boots when installing shingles on a steep-sloped roof due to the enhanced traction they provide.

The adoption of this specialized footwear in the roofing industry provides improved safety and efficiency for workers. Historically, roofers relied on standard work boots, which often lacked the necessary grip on steep or slick surfaces, increasing the risk of falls. The enhanced traction of these shoes minimizes slippage, leading to greater stability and confidence while working at heights. This, in turn, can contribute to increased productivity and reduced workplace injuries.

The following sections will delve into the specific features that make certain shoe models suitable for roofing applications, examining aspects such as sole composition, upper material durability, and overall construction designed to withstand the rigors of the job site. Furthermore, the article will present a comparative analysis of various models and brands available in the market, as well as best practices for maintaining and extending the lifespan of this specialized safety equipment.

Essential Considerations for Roofing Footwear Selection

Proper selection and utilization of specialized footwear are crucial for safety and efficiency in roofing work. The following tips provide guidance on maximizing the benefits and longevity of footwear used in this demanding trade.

Tip 1: Sole Composition is Paramount: Prioritize footwear featuring a vulcanized rubber sole. This material offers superior grip compared to traditional work boot soles, minimizing slippage on inclined surfaces. Inspect the sole regularly for wear and replace the footwear when traction diminishes.

Tip 2: Evaluate Tread Pattern: A flat, relatively smooth tread pattern maximizes surface contact and enhances grip on roofing materials. Avoid deeply lugged patterns, as they can trap debris and reduce the contact area with the roof surface.

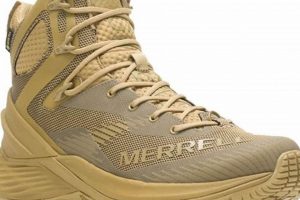

Tip 3: Prioritize Durability of Upper Material: Roofing work exposes footwear to abrasive materials and harsh weather conditions. Select footwear with a durable upper material, such as reinforced canvas or leather, to withstand the rigors of the job site. Regularly inspect the upper for tears or punctures that could compromise foot protection.

Tip 4: Consider Ankle Support: While flexibility is important, adequate ankle support is crucial for preventing injuries on uneven surfaces. Opt for footwear with a padded collar and reinforced heel counter to provide stability and reduce the risk of ankle sprains.

Tip 5: Ensure Proper Fit: Ill-fitting footwear can lead to discomfort, fatigue, and an increased risk of injury. Measure feet accurately and select footwear that provides ample toe room and a secure fit around the heel. Consider using cushioned insoles to enhance comfort and shock absorption.

Tip 6: Regular Cleaning and Maintenance: Remove debris and clean footwear regularly to maintain optimal performance. Use a brush and mild detergent to clean the soles and upper material. Allow footwear to air dry completely before storing to prevent mildew and odor buildup.

Tip 7: Rotate Footwear: Rotating between multiple pairs of footwear extends their lifespan and allows materials to dry completely, preventing bacterial growth and reducing odor. Invest in at least two pairs to ensure optimal performance and hygiene.

Adherence to these guidelines will promote a safer and more productive work environment, while also maximizing the return on investment in specialized roofing footwear.

The subsequent section will address common misconceptions regarding footwear used in roofing and offer expert recommendations for selecting the most appropriate equipment for specific roofing tasks.

1. Grip and Traction

Grip and traction are paramount characteristics in footwear designed for roofing applications. The efficacy of specialized footwear in mitigating slip hazards and enhancing worker stability hinges directly on these attributes.

- Vulcanized Rubber Soles

Vulcanized rubber, a common material in the outsoles of these types of shoe, offers a high coefficient of friction on various roofing surfaces, including asphalt shingles, metal panels, and tile. The vulcanization process enhances the rubber’s durability and resistance to wear, ensuring consistent grip performance over time. This is crucial as roofers frequently encounter diverse and often abrasive materials.

- Flat Outsole Design

A flat outsole design maximizes surface contact between the footwear and the roofing material. This contrasts with lugged or heavily treaded soles, which may reduce the contact area and compromise grip, especially on smooth or uneven surfaces. A larger contact area translates to greater frictional force, enhancing stability and reducing the likelihood of slips.

- Tread Pattern Optimization

The tread pattern on the outsole plays a critical role in channeling water and debris away from the contact area, maintaining grip even in wet or dusty conditions. A fine, multi-directional tread pattern is often preferred for roofing applications, as it provides grip in various directions without trapping excessive amounts of debris. A well-designed tread pattern also contributes to the overall flexibility of the sole, allowing it to conform to the contours of the roof surface.

- Sole Compound Hardness

The hardness of the rubber compound used in the outsole influences its grip and durability. Softer compounds tend to offer better grip on smooth surfaces but may wear down more quickly. Harder compounds are more durable but may provide less grip. Selecting the appropriate sole compound hardness requires balancing grip requirements with the expected lifespan of the footwear. Additionally, some manufacturers incorporate specialized rubber compounds designed to resist oil and chemical degradation, extending the footwear’s durability in harsh roofing environments.

The interplay of vulcanized rubber soles, flat outsole designs, optimized tread patterns, and carefully selected sole compound hardness directly affects the safety and productivity of roofing professionals. The integration of these grip-enhancing features distinguishes purpose-built roofing footwear from standard work boots, thereby minimizing the risk of falls and enhancing overall job site safety.

2. Sole Durability

Sole durability represents a critical performance parameter for specialized footwear employed in roofing. The abrasive nature of roofing materials, coupled with the repeated stress of walking and working on inclined planes, exerts significant wear on the outsole. Compromised sole durability directly translates to reduced grip, diminished stability, and an elevated risk of slips and falls. Footwear specifically designed for roofing necessitates robust sole construction using materials engineered to withstand continuous abrasion and deformation. These shoes often use a vulcanized rubber outsole, known for its abrasion resistance and flexibility.

The selection of appropriate materials and construction techniques plays a pivotal role in determining sole durability. For example, a roofing professional who installs asphalt shingles daily requires footwear with a different level of sole durability compared to someone who primarily performs inspections on smooth, metal roofs. The frequency of roof replacements in hurricane-prone areas highlights the demand for durable outsoles that can withstand prolonged exposure to debris and harsh weather conditions. Inadequate sole durability can lead to premature failure of the footwear, resulting in increased replacement costs and potential workplace hazards.

Understanding the link between sole durability and roofing-specific footwear selection is fundamental to ensuring worker safety and maximizing the lifespan of the equipment. Prioritizing footwear with high abrasion resistance, coupled with regular inspection and maintenance, directly contributes to a reduction in slip-related injuries and associated costs. Continuous research and development in sole material technology are essential for further enhancing the durability and performance of specialized footwear used in the demanding roofing industry.

3. Ankle Support

Ankle support constitutes a critical safety feature in footwear intended for roofing applications. The irregular and often sloped surfaces encountered in roofing work present a heightened risk of ankle injuries, such as sprains and strains. Footwear lacking adequate ankle support exacerbates this risk, potentially leading to worker incapacitation and increased incidence of workplace accidents. Therefore, the design and construction of roofing-specific footwear must prioritize mechanisms for providing substantial ankle stabilization.

The incorporation of features such as high-cut designs, padded collars, and reinforced heel counters directly contributes to enhanced ankle support. High-cut designs extend the upper portion of the footwear above the ankle joint, providing increased stability and limiting excessive ankle movement. Padded collars cushion the ankle and reduce friction, minimizing the risk of blisters and discomfort. Reinforced heel counters offer structural support to the heel and ankle, preventing inward or outward rolling of the foot. An example illustrates this point: a roofer traversing a steeply pitched roof benefits from footwear with a reinforced heel counter, which prevents the ankle from collapsing inward, maintaining balance and minimizing the risk of a fall. Inadequate ankle support can result in fatigue and instability, increasing the likelihood of missteps and injuries.

Understanding the relationship between ankle support and roofing safety is essential for promoting a safer work environment. Roofing contractors must prioritize the selection of footwear that provides ample ankle stabilization, and roofers themselves should be trained to recognize the importance of this feature. The challenges in achieving optimal ankle support lie in balancing stability with flexibility, as excessive rigidity can restrict movement and increase fatigue. However, advancements in footwear technology, such as the use of articulated ankle supports, are continually improving the balance between these competing demands, ultimately contributing to enhanced safety and productivity in the roofing industry.

4. Material Strength

Material strength, referring to a material’s ability to withstand applied forces without failure, is a critical determinant of the suitability of footwear for roofing applications. The demanding nature of roofing, characterized by abrasive surfaces, exposure to the elements, and repetitive physical stress, necessitates footwear constructed from robust materials. Material degradation directly impacts the lifespan and protective capabilities of the footwear, potentially compromising worker safety.

- Upper Material Resistance to Abrasion

The upper portion of footwear used in roofing is subjected to continuous abrasion from roofing materials such as shingles, tiles, and metal sheets. Materials like reinforced canvas, treated leather, and synthetic textiles with high abrasion resistance ratings are crucial for preventing premature wear and tear. For example, a roofer repeatedly kneeling on asphalt shingles can quickly degrade the upper of shoes constructed from standard canvas, leading to compromised foot protection and the need for frequent replacements. Shoes that are constructed using ballistic nylon will withstand more exposure to harsh conditions.

- Sole Adhesion and Delamination Prevention

The bond between the outsole and the upper is a critical point of failure in roofing footwear. Strong adhesive compounds and robust construction techniques are necessary to prevent delamination, particularly under conditions of extreme temperature fluctuations and prolonged exposure to moisture. Consider the scenario of a roofer working on a black roof on a hot day; the heat can weaken the adhesive bond if it’s not sufficiently strong, causing the sole to separate from the upper and rendering the footwear unusable and unsafe.

- Resistance to Puncture and Tearing

Roofing sites often present hazards such as exposed nails, sharp debris, and protruding objects. Footwear materials must exhibit high resistance to puncture and tearing to protect the wearer from foot injuries. For instance, a roofer stepping on a stray nail could suffer a serious foot injury if their footwear lacks a puncture-resistant midsole or a sufficiently dense outsole. The strength of the fabric will assist to deflect possible tears from sharp objects.

- Impact Resistance and Load Bearing Capacity

Roofing work often involves carrying heavy materials and tools, placing significant stress on the footwear. Materials with high impact resistance and load-bearing capacity are essential for preventing deformation and ensuring that the footwear provides adequate support and protection. For example, a roofer carrying a bundle of shingles across a roof subjects their footwear to considerable weight, which can compress the sole and compromise its cushioning and stability if the materials are not sufficiently strong. Choosing materials that will reduce the blow with heavy objects will reduce injuries.

The preceding discussion underscores the importance of material strength in selecting appropriate footwear for roofing tasks. The capacity of the shoe is crucial. Each elementabrasion resistance, sole adhesion, puncture resistance, and impact resistancecontributes to the overall durability, safety, and longevity of the footwear. Investing in footwear constructed from high-quality, durable materials represents a cost-effective strategy for minimizing workplace injuries and maximizing worker productivity in the demanding roofing industry.

5. Weather Resistance

Weather resistance, defined as the ability of a material or product to withstand degradation caused by exposure to environmental elements, plays a pivotal role in determining the suitability and longevity of footwear designed for roofing applications. Footwear used in this context is consistently exposed to a variety of weather conditions that can significantly impact its performance and structural integrity. Thus, understanding and addressing weather resistance is paramount for ensuring both worker safety and the durability of roofing footwear.

- Waterproofing and Water Resistance

Prolonged exposure to rain or snow can saturate footwear, leading to discomfort, reduced insulation, and potential damage to internal components. Waterproofing treatments, such as durable water repellent (DWR) coatings or waterproof membranes, are essential for preventing water penetration. Water-resistant materials, which offer a degree of protection against moisture, are also valuable in environments with intermittent rain or damp conditions. For example, prolonged exposure to standing water can weaken the adhesive bonds in the sole, leading to delamination. Therefore, materials and construction methods that minimize water absorption and promote rapid drying are highly desirable.

- UV Resistance

Ultraviolet (UV) radiation from sunlight can degrade the polymers and dyes used in footwear materials, causing fading, cracking, and reduced strength. This is particularly relevant for roofing footwear, which is often exposed to intense sunlight for extended periods. UV-resistant coatings and materials, such as UV-stabilized synthetic fabrics, help to mitigate the damaging effects of UV radiation, extending the lifespan of the footwear. The breakdown of synthetic materials used in footwear will often compromise the protective qualities, especially support, and make the footwear more susceptible to tears.

- Temperature Fluctuation Tolerance

Roofing footwear must withstand a wide range of temperature fluctuations, from extreme heat in the summer to freezing conditions in the winter. These temperature changes can cause materials to expand and contract, leading to stress and potential failure. Materials with high thermal stability and resistance to thermal shock are essential for maintaining the structural integrity of the footwear. For instance, extreme cold can cause the rubber in the sole to become brittle and crack, while excessive heat can soften adhesives and cause delamination. Using footwear that can handle changes in temperature is essential for safety.

- Chemical Resistance

Roofing work can involve exposure to various chemicals, such as solvents, adhesives, and cleaning agents. These chemicals can degrade footwear materials, causing discoloration, weakening, and reduced performance. Materials with high chemical resistance, such as certain types of synthetic rubber and treated leather, are necessary for protecting the footwear from chemical damage. Exposure to these chemicals can compromise the grip and make the footwear slippery, and unsafe.

The aspects of weather resistance contribute directly to the longevity, performance, and safety of specialized footwear for roofing. By prioritizing materials and construction techniques that address these weather-related challenges, manufacturers can produce footwear that provides superior protection and durability for roofing professionals.

6. Weight Balance

Weight balance in footwear designed for roofing applications is a critical factor impacting stability, agility, and overall worker safety. Footwear with an uneven distribution of weight can cause instability, leading to increased fatigue and a higher risk of slips, trips, and falls on inclined or uneven surfaces. In the context of roofing, where workers operate at heights and often carry heavy materials, maintaining optimal weight balance becomes particularly crucial. The design and construction of specialized roofing footwear must, therefore, prioritize even weight distribution to minimize these risks.

An example of the effect of proper weight balance can be seen when comparing traditional work boots to specialized roofing shoes. Traditional work boots, often designed for general construction, may have a higher heel or a bulky sole, creating an uneven weight distribution. This can cause the wearer to lean forward, increasing strain on the ankles and lower back, and reducing stability on sloped surfaces. Conversely, roofing footwear typically features a flat sole and a low profile, distributing weight more evenly across the foot. This design enhances stability and allows the worker to maintain a more natural posture, reducing fatigue and improving agility. The proper weight distribution helps a roofer to maintain center of gravity.

In conclusion, weight balance is an essential component of specialized roofing footwear. Prioritizing even weight distribution through appropriate design and material selection can significantly enhance worker safety, reduce fatigue, and improve overall productivity on the job site. Challenges remain in balancing weight distribution with other performance factors, such as durability and weather resistance. However, ongoing research and development efforts are focused on optimizing all aspects of roofing footwear design to ensure the highest levels of safety and performance.

7. Flexibility

Flexibility, in the context of specialized footwear for roofing, refers to the ability of the shoe to bend and conform to the contours of the roof surface. This characteristic directly influences the wearer’s range of motion, comfort, and stability. Footwear that lacks sufficient flexibility can restrict movement, leading to fatigue, reduced agility, and an increased risk of missteps. Conversely, excessive flexibility can compromise support and stability, potentially increasing the risk of ankle injuries. The optimal level of flexibility in roofing footwear represents a balance between these competing demands.

The design and materials used in roofing footwear significantly impact its flexibility. Skate-inspired shoes often incorporate a vulcanized rubber sole, which provides both grip and a degree of flexibility. The upper material, whether canvas, leather, or a synthetic fabric, also contributes to the overall flexibility of the shoe. A stiffer upper material will restrict movement more than a softer, more pliable material. For example, a roofer working on a steeply pitched roof needs footwear that allows them to bend their foot at the toes and ankle to maintain contact with the roof surface. Shoes with a rigid sole and upper would hinder this movement, increasing the risk of slippage. The placement of flex grooves in the sole can further enhance flexibility by allowing the shoe to bend more easily at specific points.

Ultimately, flexibility is a vital component of specialized roofing footwear, contributing to enhanced comfort, agility, and safety on the job site. Finding the right balance between flexibility and support is crucial for optimizing performance and minimizing the risk of injuries. The selection of appropriate materials and design features plays a key role in achieving this balance. While skate-inspired designs often offer a good starting point, roofers should carefully evaluate the specific features and construction of each shoe to ensure that it meets the demands of their particular roofing tasks.

Frequently Asked Questions About Skate Shoes for Roofing

The following section addresses common inquiries regarding the use of skate-style footwear in roofing applications. The information presented aims to clarify misconceptions and provide factual insights for making informed decisions about safety and performance.

Question 1: Are all skate shoes suitable for roofing work?

No. While many roofing professionals adapt skate shoe designs for their work, standard skate shoes may lack necessary safety features such as reinforced uppers, puncture-resistant soles, and adequate ankle support. Selection should prioritize models specifically designed or adapted for demanding work environments.

Question 2: How does the grip of skate-style shoes compare to that of traditional work boots on roofing surfaces?

Skate-style shoes designed for roofing often feature flat, vulcanized rubber soles that provide a larger contact area and enhanced grip compared to the lugged soles of traditional work boots. This can result in superior traction on smooth or inclined roofing surfaces.

Question 3: Do skate-style shoes offer sufficient protection against common roofing hazards?

The level of protection varies significantly depending on the specific shoe model. Standard skate shoes may not offer adequate protection against punctures, impacts, or chemical exposure. Roofing-specific or adapted models typically incorporate reinforced materials and safety features to address these hazards.

Question 4: What is the expected lifespan of skate-style shoes used for roofing?

The lifespan is influenced by factors such as the frequency of use, the type of roofing work performed, and the quality of the shoe’s construction. Regular inspection and maintenance are essential for maximizing the lifespan and ensuring continued safety.

Question 5: Are there specific regulations or standards governing the use of skate-style shoes in roofing?

Regulations may vary depending on the jurisdiction. It is imperative to consult local safety guidelines and employer policies to ensure compliance with applicable standards. Furthermore, ensure selected footwear aligns with hazard assessments for specific tasks.

Question 6: Can skate-style shoes be modified to enhance their suitability for roofing?

Modifications such as adding protective toe caps or reinforcing the soles may improve the safety and durability of skate-style shoes. However, modifications should be performed by qualified professionals and should not compromise the shoe’s structural integrity or intended function.

In conclusion, the utilization of skate-style footwear in roofing warrants careful consideration. While certain designs may offer advantages in terms of grip and flexibility, it is crucial to prioritize safety features and ensure compliance with relevant regulations. Proper selection, maintenance, and modification, when appropriate, are essential for maximizing the benefits and minimizing the risks associated with this type of footwear.

The following section will delve into case studies and real-world examples of roofing professionals who have successfully utilized skate-style footwear, highlighting best practices and lessons learned.

Skate Shoes for Roofing

This exploration has detailed the complex relationship between skate shoes and the roofing profession. It has examined the specific characteristics, such as sole composition, material strength, and flexibility, that render certain footwear types more suitable for the demanding environment of roofing work. The analysis has underscored the importance of prioritizing safety, durability, and compliance with industry regulations when selecting footwear for this occupation.

Given the inherent risks associated with roofing, a thorough assessment of footwear options remains paramount. While skate-inspired designs may offer benefits in terms of grip and maneuverability, roofing professionals must exercise caution and prioritize footwear that provides comprehensive protection against workplace hazards. Continued research and development in specialized footwear technology will be crucial for enhancing worker safety and productivity in the roofing industry. The ultimate decision must reflect a commitment to minimizing risk and maximizing performance in this challenging profession.