Protective coverings for the blades of ice skates, typically made of hard plastic or rubber, allow skaters to walk on surfaces other than ice without damaging the sharp edges. These coverings shield the blades from contact with concrete, tile, or other abrasive materials, preventing nicks, dulling, and potential injury. For example, a skater exiting the rink and traversing a hallway to the locker room will utilize these blade protectors.

Employing these protective accessories is crucial for maintaining the blade’s sharpness and extending its lifespan. This translates to enhanced performance on the ice and reduced frequency of blade sharpening, resulting in cost savings over time. Historically, skaters may have used softer materials like cloth or leather, but modern materials offer significantly greater protection and durability.

The subsequent sections will delve into the various types available, their construction materials, proper usage techniques, and maintenance procedures to ensure optimal protection and longevity of skating equipment. Specific recommendations will be provided to aid in selecting the most appropriate protective gear for individual skating needs.

Essential Usage and Maintenance Tips

Optimal performance and longevity of skating blades are contingent upon proper handling and safeguarding. The following guidelines outline best practices for utilizing and preserving blade protection accessories.

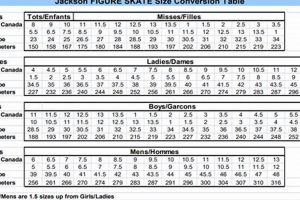

Tip 1: Select the Appropriate Size: Ensure the chosen protective covering fits snugly and securely on the blade. Oversized or ill-fitting coverings can slip off, exposing the blade to potential damage. A properly sized guard provides full coverage and prevents movement during use.

Tip 2: Use Immediately After Skating: Affix the blade protection immediately after exiting the ice surface. Delaying this action increases the risk of accidental contact with abrasive surfaces. Prompt application preserves blade sharpness and minimizes potential damage.

Tip 3: Avoid Prolonged Storage: Remove blade protection coverings after each use and allow both the blades and coverings to air dry. Prolonged moisture exposure can lead to rust formation on the blades and degradation of the protective material. Prioritize proper ventilation and drying.

Tip 4: Clean Regularly: Periodically clean the blade protection coverings with a mild detergent and water solution. Accumulated dirt and debris can abrade the blades over time. Regular cleaning removes contaminants and maintains the integrity of the protective barrier.

Tip 5: Inspect for Wear and Tear: Routinely examine the blade protection coverings for signs of damage, such as cracks, tears, or excessive wear. Replace worn or damaged coverings promptly to ensure continued protection. Proactive replacement prevents potential blade damage and maintains safety.

Tip 6: Utilize Soakers for Storage: When storing skates for extended periods, use absorbent soakers made of cloth or terrycloth to wick away moisture from the blades. This reduces the risk of rust and corrosion during storage. Combine with blade protection for comprehensive preservation.

Adhering to these recommendations will contribute significantly to the extended lifespan and optimal performance of skating blades, resulting in enhanced on-ice experience and reduced equipment replacement costs.

The subsequent sections will address specific types and advanced preservation strategies for specialized skating disciplines.

1. Protection

The primary function of blade protection is, fundamentally, protection. This safeguard acts as a crucial barrier between the delicate edges of ice skate blades and the harsh realities of surfaces beyond the ice rink. Direct contact with concrete, tile, or even rubberized flooring can result in nicks, scratches, and the dulling of the blade’s edge. Consequently, this damage compromises the skater’s control and performance on the ice. Without adequate protection, the frequency of blade sharpening increases significantly, resulting in higher maintenance costs and potential reduction in the blade’s lifespan. A tangible example lies in observing skaters transitioning from the ice to the locker room; without blade protection, the briefest walk across a tiled floor can inflict noticeable damage. Therefore, the act of protection, facilitated by these blade coverings, directly preserves blade integrity.

The level of protection offered varies based on material composition and design. Hard plastic or rubber coverings provide robust defense against physical impact and abrasion. Softer materials, like cloth soakers, primarily offer protection against rust by wicking away moisture. While these offer some blade security, they are not intended for walking on hard surfaces. The selection of appropriate blade protection must correlate with the skater’s environment and anticipated use. For instance, a figure skater executing complex routines requires guards with enhanced durability and grip to prevent slippage during off-ice practice. Protection also extends to the skater’s surroundings, preventing accidental damage from sharp blades to flooring, equipment bags, or other individuals.

In summation, the concept of protection forms the cornerstone of blade guard utilization. It encompasses the dual benefit of preserving the skate’s performance edge and safeguarding the skater and their environment. The ongoing challenge lies in continually refining materials and designs to maximize protection while maintaining ease of use and affordability. A deeper understanding of this protective role enables skaters to make informed decisions, ensuring their equipment remains in optimal condition, thereby enhancing their overall skating experience.

2. Durability

Durability, in the context of blade protection, directly influences the lifespan and effectiveness of the protective covering. The material composition and structural design dictate the guard’s ability to withstand repeated use, abrasion, and impact. Insufficient durability results in premature wear and tear, rendering the guard ineffective and exposing the skate blade to potential damage. For example, guards made from low-grade plastic may crack or break after minimal use, particularly when subjected to the weight of the skater walking on hard surfaces. Conversely, guards constructed from high-density polymers or reinforced rubber compounds offer superior resistance to physical stress, extending their operational life and consistently safeguarding the blade.

The practical significance of durability extends beyond mere longevity. A durable guard maintains its structural integrity, ensuring a secure and consistent fit on the blade. Warping, cracking, or deformation compromises this fit, increasing the risk of slippage and accidental blade exposure. Moreover, durable guards effectively resist the absorption of moisture and debris, minimizing the potential for corrosion and abrasion of the blade itself. For instance, a guard that retains moisture can contribute to rust formation on the blade, even during storage. Selecting guards with inherent resistance to degradation ensures consistent protection under a variety of environmental conditions.

In conclusion, durability is a critical attribute of effective blade protection. It is a primary determinant of the guard’s lifespan, protective capabilities, and long-term cost-effectiveness. Investing in durable guards translates to reduced replacement frequency, enhanced blade protection, and improved overall value. Furthermore, understanding the importance of durability empowers skaters to make informed purchasing decisions, selecting guards that provide reliable and consistent protection for their valuable skating equipment.

3. Blade Preservation

Blade preservation constitutes a critical aspect of ice skate maintenance, directly impacting performance and longevity. The employment of protective guards is intrinsically linked to this preservation, serving as the primary means of safeguarding blades from detrimental external factors.

- Mitigation of Surface Damage

Contact with non-ice surfaces such as concrete, tile, or rubberized flooring invariably leads to edge degradation through nicks, scratches, and dulling. Blade protection minimizes this direct contact, preserving the integrity of the blade’s sharpened edge. For instance, traversing a locker room or walking to and from the ice surface presents numerous opportunities for damage that protective guards effectively mitigate.

- Prevention of Rust and Corrosion

Moisture exposure, a common occurrence following ice skating sessions, accelerates the oxidation process and promotes rust formation on blades. Certain guard types, particularly those incorporating absorbent materials or designed for ventilation, aid in wicking away moisture and preventing corrosion. This is especially relevant during storage, where prolonged dampness can cause significant damage if left unaddressed.

- Maintenance of Blade Profile

Consistent blade geometry is crucial for optimal skating performance. Damage to the blade, even seemingly minor, can alter the intended profile, affecting glide, edge control, and overall stability. Blade protection helps maintain the original profile by preventing structural damage from external forces, thereby preserving the skater’s accustomed feel and performance on the ice.

- Reduction in Sharpening Frequency

Frequent blade sharpening, while necessary, gradually reduces the blade’s usable lifespan. By minimizing blade damage through consistent use of protective guards, skaters can extend the intervals between sharpenings, ultimately prolonging the overall lifespan of the blades and reducing maintenance costs. This is particularly significant for competitive skaters who rely on precise edge control and require frequent sharpening under unprotected conditions.

The interrelationship between blade protection and preservation is undeniable. Guards offer a tangible means of extending blade life, maintaining performance characteristics, and minimizing maintenance requirements. Effective implementation of blade protection strategies directly contributes to optimized skating experience and reduced long-term equipment expenses.

4. Proper Fit

The effectiveness of blade protection hinges directly on achieving a proper fit. This fit refers to the conformity between the protective guard and the specific contours of the ice skate blade. Ill-fitting guards, whether too loose or too tight, compromise the intended protective function, potentially leading to blade damage or hazardous situations for the skater. For example, an oversized guard may slip off during off-ice walking, exposing the blade to abrasive surfaces. Conversely, an excessively tight guard could exert undue pressure on the blade, potentially causing deformation or accelerated wear. Therefore, the precise correspondence between guard and blade is paramount for optimal safeguarding.

The selection process necessitates careful consideration of blade size and style. Skate blades vary in length, width, and curvature, demanding correspondingly sized guards. A guard intended for a figure skate blade will likely prove unsuitable for a hockey skate blade, and vice versa. Additionally, the attachment mechanism plays a crucial role. Spring-loaded mechanisms, for instance, must provide adequate tension to secure the guard without causing undue stress on the blade. Correct installation and adjustment are equally important; improperly fitted guards can shift or detach, negating their protective capabilities. The practical implication lies in meticulously verifying the fit before each use, ensuring a secure and stable placement on the blade.

In summary, proper fit is not merely a desirable attribute, but a fundamental prerequisite for effective blade protection. It dictates the guard’s ability to prevent damage, maintain secure placement, and minimize the risk of accidents. The challenges reside in the variability of blade designs and the potential for guards to lose their original shape over time. Emphasizing the significance of proper fit underscores the need for skaters to prioritize careful selection, installation, and ongoing inspection of their blade protection, ensuring their valuable equipment remains adequately safeguarded.

5. Material Quality

The durability and protective efficacy of blade protection are inextricably linked to material quality. The selection of appropriate materials directly determines the guard’s capacity to withstand abrasion, impact, and environmental factors, ultimately influencing its lifespan and effectiveness in safeguarding the blade. Inadequate material selection results in premature wear, compromised protection, and potential blade damage. For example, guards fabricated from brittle, low-density plastics are prone to cracking and shattering under stress, rendering them ineffective in preventing contact between the blade and abrasive surfaces. This necessitates frequent replacements and exposes the blade to avoidable risks. Conversely, guards constructed from high-density polymers, reinforced rubber compounds, or composite materials offer superior impact resistance and longevity, ensuring consistent protection over extended periods. The initial investment in high-quality materials translates to long-term cost savings and enhanced blade preservation.

Beyond mechanical resilience, material quality impacts the guard’s resistance to moisture and temperature fluctuations. Materials susceptible to water absorption can promote corrosion on the blade, even when the guard is intended to provide protection. Similarly, materials that become brittle or deformed under extreme temperatures compromise the fit and stability of the guard, potentially leading to slippage or detachment. For instance, guards stored in unheated environments during winter months may crack due to the embrittlement of the plastic, while guards exposed to direct sunlight can warp and lose their original shape. Selecting materials with inherent resistance to these environmental factors ensures consistent performance and reliable protection regardless of external conditions. Furthermore, the surface finish and texture of the material influence its ability to grip the blade securely and prevent slippage during off-ice movement. Smooth, slippery materials offer minimal traction, increasing the risk of accidental blade exposure. Therefore, material quality encompasses not only structural integrity but also functional properties that contribute to the overall effectiveness of the blade protection.

In conclusion, material quality constitutes a fundamental consideration in the selection of blade protection. It dictates the guard’s lifespan, protective capabilities, and resistance to environmental factors. Comprehending the impact of material properties empowers skaters to make informed purchasing decisions, prioritizing durability, resilience, and functional effectiveness. Investing in high-quality materials translates to enhanced blade preservation, reduced maintenance costs, and improved overall safety for both the skater and their equipment. The ongoing advancements in material science offer continued opportunities to refine blade protection, further enhancing its ability to safeguard valuable skating equipment.

6. Safe Transit

The function of safe transit is intrinsically linked to protective blade coverings, addressing the inherent risks associated with transporting ice skates. Unprotected blades pose a significant hazard, capable of causing injury to the skater, bystanders, or damage to carrying cases and other equipment. Specifically, the sharp edges can easily cut through fabrics, puncture bags, or inflict lacerations if mishandled. Protective coverings mitigate these risks by encapsulating the blades, creating a barrier that prevents accidental contact and minimizes the potential for harm. Therefore, safe transit, in the context of ice skates, directly relies on the utilization of blade protection as a preventative measure. For example, transporting skates without guards on public transportation presents a clear risk, where accidental bumps or jostling could lead to injury. Conversely, secured blades within protective coverings significantly reduce this risk, promoting safe and responsible transport.

Furthermore, these coverings contribute to the preservation of other equipment during transit. Sharp blades can damage the lining of skate bags, tear clothing stored alongside the skates, or cause scratches on surrounding surfaces. Protective coverings shield against such damage, maintaining the integrity of carrying cases and preventing wear and tear on associated belongings. The selection of appropriate coverings must also consider the method of transportation. For air travel, more robust and impact-resistant guards may be necessary to withstand the handling procedures and potential turbulence. The integration of secure fastening mechanisms, such as straps or clips, further enhances safe transit by preventing the guards from dislodging during movement. Cases can be cited of airport handling damaging unprotected blade.

In conclusion, the concept of safe transit underscores the importance of blade coverings as a crucial safety component. These coverings not only protect individuals and their surroundings but also contribute to the longevity of skating equipment. The challenge lies in continually improving the design and materials of blade coverings to maximize protection while maintaining ease of use and portability. Recognizing the practical significance of safe transit fosters a culture of responsibility among skaters, promoting safer practices and minimizing the potential for accidents during transport.

Frequently Asked Questions

The following section addresses common inquiries regarding protective blade coverings for ice skates, providing concise and informative answers to ensure proper understanding and utilization.

Question 1: What is the primary function of these guards?

The primary function is to protect the sharp edges of ice skate blades from damage when walking on surfaces other than ice. This prevents nicks, dulling, and other forms of wear that can compromise performance.

Question 2: Are all blade protection types suitable for all skate types?

No, different skate types (e.g., figure skates, hockey skates) have different blade shapes and sizes. It is crucial to select guards specifically designed for the intended skate type to ensure a proper and secure fit.

Question 3: How often should ice skate guards be replaced?

Replacement frequency depends on usage and material quality. Guards should be inspected regularly for signs of wear, such as cracks or tears, and replaced immediately if damage is detected.

Question 4: Is it necessary to remove guards immediately after skating?

Yes, prolonged storage of skates with guards attached can trap moisture, leading to rust and corrosion. It is recommended to remove the guards and allow both the blades and the guards to air dry.

Question 5: Can blade coverings prevent the need for blade sharpening?

While they can significantly reduce the frequency of sharpening by minimizing damage, they cannot eliminate the need entirely. Regular sharpening remains essential for maintaining optimal blade performance.

Question 6: Are all materials equally effective for blade protection?

No, materials vary significantly in their protective capabilities. Hard plastic and rubber guards offer greater protection against impact and abrasion compared to softer materials like cloth soakers, which primarily address moisture absorption.

Proper use and maintenance of blade protection extend the life of ice skate blades, enhance on-ice performance, and promote safety. Adhering to these guidelines ensures optimal protection for valuable skating equipment.

The subsequent sections will explore advanced techniques and considerations for preserving skating equipment in specialized disciplines.

Conclusion

The preceding analysis has elucidated the multi-faceted significance of protective blade coverings. Their role extends beyond mere accessory status, functioning as integral components in preserving the integrity, performance, and longevity of ice skate blades. The discussion underscored the importance of material quality, proper fit, durability, and consistent maintenance in maximizing their protective efficacy. Furthermore, the critical function of promoting safe transit, thereby mitigating potential hazards to both the skater and their surroundings, was thoroughly examined.

Therefore, the diligent selection, application, and maintenance of these coverings represent a crucial investment in the skater’s equipment and safety. A continued emphasis on innovation in material science and design will undoubtedly yield further advancements in blade protection technology, ensuring optimal safeguarding of these essential tools for ice sports enthusiasts and professionals alike. Recognizing the fundamental importance of ice skate guards contributes to a culture of responsible equipment stewardship and enhanced performance within the skating community.

![Find the Perfect Ice Skates for Women | [Brand] Learn to Surf & Skate: A Beginner's Step-by-Step Guide Find the Perfect Ice Skates for Women | [Brand] | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/01/th-835-300x200.jpg)