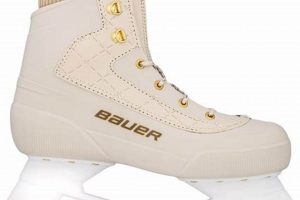

These are a type of footwear designed specifically for gliding across ice surfaces. They consist of a boot, typically made of leather or synthetic materials, attached to a metal blade. The blades allow for efficient movement and maneuverability on ice, enabling activities such as ice hockey, figure skating, and recreational skating.

Their significance lies in providing the necessary equipment for participation in various winter sports and leisure activities. The quality of the boot construction impacts comfort, support, and performance. Blade design influences speed, agility, and control. Historically, improvements in materials and manufacturing techniques have led to enhancements in skate performance and durability, contributing to the evolution of ice-based sports and recreation.

The following sections will delve deeper into the construction, features, selection considerations, and maintenance of this specialized equipment, providing a comprehensive understanding for potential users and enthusiasts.

Tips

The following guidelines are provided to maximize the lifespan, performance, and safety of this equipment.

Tip 1: Proper Sizing is Paramount: Incorrect sizing can lead to discomfort, blisters, and reduced performance. Professional fitting is recommended to ensure the heel is locked in place and the toes have minimal contact with the boot’s end. Consider the manufacturer’s specific sizing charts, as they may vary.

Tip 2: Consistent Drying Prevents Degradation: Moisture accelerates corrosion of the blade and weakens the boot’s internal structure. After each use, remove the boot from the bag, wipe the blade with a dry cloth, and allow the skates to air dry in a well-ventilated area. Boot dryers can be utilized to expedite the drying process.

Tip 3: Blade Sharpening is Essential for Performance: Dull blades compromise edge control and gliding efficiency. Sharpening frequency depends on usage, but regular maintenance is recommended. Professional sharpening services ensure the correct hollow is maintained on the blade, optimizing performance characteristics.

Tip 4: Avoid Walking on Hard Surfaces Without Protection: Concrete, asphalt, and other hard surfaces quickly dull the blade edges. Skate guards should be used when walking on these surfaces to protect the blades from damage.

Tip 5: Proper Lacing Technique Enhances Support and Fit: Lacing should be snug but not overly tight, allowing for ankle flexion and extension. Skates should be laced from the bottom up, ensuring even pressure distribution. Consider using waxed laces, which provide a more secure and consistent hold.

Tip 6: Regular Inspection for Damage is Crucial for Safety: Examine the boot, blade, and rivets for signs of wear and tear. Loose rivets, cracks in the boot, or significant blade damage can compromise safety and performance. Damaged components should be repaired or replaced promptly.

Adhering to these recommendations will significantly extend the life of the product, maintain optimal performance, and ensure user safety.

The subsequent section will address common issues encountered with this equipment and offer solutions for troubleshooting and repair.

1. Boot Construction

Boot construction directly impacts the performance, comfort, and durability of ice skates. The materials and design used in the boot dictate the level of support, flexibility, and protection afforded to the skater’s foot and ankle. Variations in construction methods can lead to significant differences in the overall skate experience. For example, a boot constructed with multiple layers of heat-moldable materials allows for a custom fit, enhancing comfort and power transfer. Conversely, a poorly constructed boot may lack adequate support, leading to instability and an increased risk of injury.

The composition of the boot also influences its ability to withstand the rigors of skating. High-end models often incorporate carbon fiber or composite materials to maximize stiffness and energy transfer. These materials allow skaters to generate more power with each stride. The liner within the boot plays a critical role in moisture management and comfort. Liners constructed from moisture-wicking materials help keep the foot dry and prevent blisters. Furthermore, the design of the tongue contributes to forward flex and impact protection. Thick, padded tongues can mitigate lace bite and absorb impacts from pucks or collisions.

Understanding the nuances of boot construction enables skaters to select the equipment best suited to their needs and skating style. Whether prioritizing comfort for recreational skating or maximizing performance for competitive hockey, a well-constructed boot is essential. The selection process should consider the skater’s foot shape, skating frequency, and performance goals. Ultimately, the quality of the boot construction directly correlates with the skater’s ability to perform at their best and enjoy the activity safely.

2. Blade Material

Blade material fundamentally dictates the performance characteristics of ice skates. The interaction between the blade and the ice surface directly affects glide, edge control, and overall skating efficiency. Consequently, the choice of blade material is a critical design consideration, impacting the skater’s ability to execute maneuvers and maintain stability. Stainless steel is a common choice due to its balance of hardness, corrosion resistance, and affordability. Higher-end models frequently employ advanced alloys or coatings to enhance edge retention and reduce friction, resulting in improved speed and agility on the ice. The specific alloy composition, heat treatment processes, and surface finishing techniques all contribute to the blade’s final properties and performance.

Different blade materials offer distinct advantages depending on the intended application. For instance, figure skates prioritize edge control for intricate jumps and spins, often utilizing blades with a higher carbon content to maintain a sharper edge for longer periods. Hockey skates, on the other hand, require a balance of speed, agility, and durability to withstand the high-impact nature of the sport. As such, hockey skate blades may incorporate tougher alloys to resist bending or breaking during collisions. The blade’s profile, including its curvature and thickness, also influences its performance characteristics. A deeper radius of hollow allows for greater edge engagement, while a flatter profile promotes faster gliding speed. Blade materials are typically tempered with advanced technological machines to achieve the proper durability for performance.

In summary, the selection of blade material directly correlates with the intended use and performance expectations of ice skates. Understanding the properties of different materials and their impact on blade characteristics is essential for both manufacturers and skaters. Advances in materials science continue to drive innovation in blade design, leading to enhanced performance and improved skating experiences. The long-term durability and edge retention of the chosen material translate directly into cost-effectiveness and reduced maintenance requirements, influencing the overall value proposition of the skates.

3. Ankle Support

Ankle support is a critical design element in ice skates, directly influencing stability, control, and injury prevention. Its effectiveness is paramount for skaters of all skill levels, impacting performance and safety. Proper ankle support ensures that the skater’s movements are efficiently translated to the ice, reducing the risk of strains and sprains.

- Boot Stiffness and Stability

The degree of stiffness in the skate boot significantly contributes to ankle support. Stiffer boots offer greater stability, particularly during lateral movements and sharp turns. This is especially important for hockey players and figure skaters who require precise control and rapid changes in direction. A rigid boot minimizes ankle flexion, preventing excessive pronation or supination, which can lead to injuries. However, excessive stiffness can limit mobility, making it essential to find a balance that suits the skater’s skill level and skating style.

- Internal Padding and Contouring

The internal padding and contouring of the skate boot play a crucial role in providing a snug and secure fit around the ankle. Strategically placed padding minimizes movement within the boot, enhancing stability and comfort. Contoured designs that conform to the natural shape of the ankle provide customized support, reducing pressure points and preventing chafing. High-density foams and gel-based materials are often used to provide cushioning and shock absorption, further protecting the ankle from impacts and vibrations.

- Lacing System and Closure Mechanisms

The lacing system and closure mechanisms contribute significantly to ankle support by allowing skaters to customize the fit of the boot. Traditional lacing systems enable precise adjustments to be made throughout the boot, providing a secure and supportive fit around the ankle. Power straps, buckles, or other closure mechanisms can further enhance ankle stability by providing additional reinforcement and preventing the boot from loosening during skating. The design and placement of these elements must be carefully considered to optimize support and comfort without restricting movement.

- Heel Lock and Ankle Stabilization Features

Effective ankle support relies on a secure heel lock, which prevents the heel from lifting or sliding within the boot. Heel lock systems, such as contoured heel cups or integrated stabilizers, help to maintain proper alignment of the foot and ankle, reducing the risk of instability and injury. Ankle stabilization features, such as lateral supports or reinforced ankle collars, provide additional protection and prevent excessive ankle movement. These features are particularly beneficial for skaters who are prone to ankle injuries or require extra support for challenging maneuvers.

Collectively, these facets of ankle support in ice skates work synergistically to provide skaters with the stability, control, and protection they need to perform at their best and minimize the risk of injury. The effectiveness of ankle support depends on the proper fit, design, and construction of the skates, as well as the skater’s individual anatomy and skating style. Choosing skates with adequate ankle support is essential for skaters of all levels, from beginners to elite athletes.

4. Heat Molding

Heat molding is a customization process applied to some models of equipment, enabling the boot to conform more closely to the individual user’s foot shape. This is achieved by heating the skate boot, typically in a specialized oven or using a heat gun, to make the materials more pliable. As the boot cools, it retains the shape of the foot, resulting in a more personalized and comfortable fit. The process aims to reduce pressure points, improve energy transfer, and enhance overall performance. A real-life example is a skater experiencing persistent discomfort due to bunions; heat molding can create space within the boot, alleviating pressure on the affected area.

The practical significance of heat molding lies in its ability to address common fit issues. Standard skate sizes often do not accommodate variations in foot width, arch height, or ankle shape. Heat molding allows retailers or trained technicians to fine-tune the fit, optimizing comfort and performance. However, it is essential to note that not all models are designed to be heat molded, and attempting to mold a non-moldable boot can cause damage. The effectiveness of heat molding also depends on the materials used in the boot construction and the skill of the technician performing the process.

In summary, heat molding is a valuable feature in select models, offering a pathway to enhanced fit and comfort. While it addresses many common fit issues, it is not a universal solution and requires careful consideration of boot compatibility and proper execution. Understanding the limitations and potential benefits of heat molding is crucial for consumers seeking a customized fit and improved skating experience.

5. Blade Sharpening

The efficacy of ice skates, irrespective of the manufacturer, fundamentally relies on the condition of their blades. Sharp blades provide the necessary edge control for efficient gliding, turning, and stopping. Blade sharpening, therefore, is not merely maintenance but a critical determinant of performance and safety. With CCM ice skates, proper blade sharpening ensures that the skater can maximize the potential of the equipment, whether for recreational use, figure skating, or ice hockey. Neglecting blade sharpening results in diminished performance, increased fatigue, and a heightened risk of falls. For example, hockey players with dull blades expend more energy trying to maintain speed and control, while figure skaters struggle to execute precise edges and landings.

The process of blade sharpening involves creating a hollow ground into the blade’s underside, forming two distinct edges. The depth of this hollow, often referred to as the “radius of hollow” or ROH, dictates the blade’s bite into the ice. A deeper hollow provides more grip, ideal for beginners or those requiring enhanced control. A shallower hollow offers increased glide and speed, preferred by experienced skaters and hockey players. Specialized equipment and trained technicians are required to achieve the optimal ROH for a specific skater’s needs and preferences. Furthermore, blade sharpening must be consistent, ensuring that both edges are uniform and parallel. Imbalances in edge sharpness can lead to instability and unpredictable performance.

In conclusion, blade sharpening is an indispensable component of CCM ice skate maintenance, directly influencing performance, safety, and enjoyment. Regular sharpening, performed by a qualified technician and tailored to the skater’s specific requirements, is essential to realize the full potential of these skates. The longevity of the blades and the skater’s skill development are inextricably linked to consistent and correct blade maintenance. Failure to prioritize blade sharpening presents a significant impediment to progress and increases the risk of accidents on the ice.

6. Lace System

The lace system constitutes a fundamental component of skates, directly influencing fit, support, and performance. Its primary function involves securing the foot within the boot, enabling efficient transfer of energy and precise control on the ice. The specific design and materials employed in the lace system dictate its effectiveness and durability. For example, a poorly designed system can lead to uneven pressure distribution, causing discomfort and hindering performance, while a robust system ensures a snug, consistent fit, maximizing stability and responsiveness.

Different types of lace systems are present on various models. Traditional lacing, featuring eyelets along the boot, offers a high degree of adjustability. Waxed laces, a common upgrade, enhance grip and prevent loosening during use. Some models incorporate specialized zones or power straps to provide targeted support in critical areas like the ankle. An inadequate lace system can result in slippage, reduced ankle stability, and compromised edge control. Conversely, a properly fitted and maintained system contributes to improved skating efficiency and reduced risk of injury. Real-world examples include hockey players experiencing lace bite due to over-tightening and figure skaters relying on secure lacing for precise jumps and landings. The tension and position of each lace segment, as they cross over the tongue and ankle, impact how well a foot sits into a ccm ice skates’s interior boot.

In summary, the lace system is an integral element of and significantly impacts a skater’s overall experience. Its design, materials, and proper adjustment are crucial for achieving optimal fit, support, and performance. Challenges related to lace maintenance, such as fraying or breakage, necessitate timely replacement to avoid compromising skate integrity. Its design, materials, and proper adjustment are crucial for achieving optimal fit, support, and performance. Understanding the nuances of lacing is essential for skaters seeking to maximize their potential and minimize the risk of discomfort or injury on the ice.

7. Rivets Integrity

Rivets, small but critical fasteners, play an indispensable role in the structural integrity and performance. In this context, their robustness directly affects the reliability, safety, and longevity of the equipment.

- Function and Load Distribution

Rivets serve to securely connect the blade to the boot, enduring significant stress during skating. Their primary function is to distribute the load evenly across the connection points, preventing localized stress concentrations that could lead to failure. For example, during sharp turns or high-impact landings, rivets are subjected to considerable shear and tensile forces. Failure of even a single rivet can compromise the entire assembly, potentially leading to blade detachment and subsequent injury.

- Material Composition and Corrosion Resistance

The material composition of rivets is a crucial factor in determining their durability and resistance to corrosion. Rivets are commonly made from steel or aluminum alloys, each offering specific advantages in terms of strength and weight. However, exposure to moisture and ice can accelerate corrosion, weakening the rivets over time. Consequently, manufacturers often employ corrosion-resistant coatings or treatments to prolong the lifespan of rivets and maintain their structural integrity. The choice of material must balance cost, weight, and resistance to environmental factors.

- Inspection and Maintenance Procedures

Regular inspection of rivets is essential for identifying signs of wear, corrosion, or damage. Visual inspection can reveal loose rivets, cracks, or discoloration, indicating potential weaknesses in the connection. Maintenance procedures, such as tightening loose rivets or replacing damaged ones, are crucial for preserving the integrity of the assembly. Neglecting these procedures can lead to catastrophic failure, particularly in high-performance skating applications. It is imperative that skaters and maintenance personnel adhere to recommended inspection and maintenance schedules to ensure continued safety and reliability.

- Impact on Performance and Safety

The integrity of rivets directly impacts the skater’s performance and safety. Securely fastened blades provide consistent and predictable performance, allowing skaters to execute maneuvers with confidence. Conversely, loose or damaged rivets can compromise stability and control, increasing the risk of falls and injuries. In competitive skating, where precision and consistency are paramount, even minor rivet issues can significantly detract from performance. Therefore, maintaining rivets’ integrity is not just a matter of prolonging the lifespan of the skates; it is a fundamental aspect of skater safety and performance optimization. The presence of loose rivets on skating equipment can become a tripping hazard.

In conclusion, the structural integrity and performance hinges significantly on the robustness and maintenance of its rivets. Their role in load distribution, material composition, and the need for diligent inspection underscore their importance in ensuring skater safety and optimal performance.

Frequently Asked Questions

The following questions address common inquiries and concerns regarding utilization and maintenance.

Question 1: What constitutes the optimal method for determining the correct size?

Professional fitting at a reputable skate shop is highly recommended. Foot measurements should be taken while wearing socks of appropriate thickness. Individuals should consult manufacturer-specific sizing charts, as sizes can vary between brands and models. A proper fit ensures comfort, performance, and injury prevention.

Question 2: How frequently should the blades undergo sharpening?

Sharpening frequency depends on usage intensity, ice conditions, and skating style. Blades should be sharpened when edge control diminishes, typically every 10-20 hours of skating. Professional sharpening services are advised to ensure proper edge alignment and hollow depth.

Question 3: What is the appropriate technique for drying after each use?

Immediately after use, the blades should be thoroughly dried with a clean, dry cloth to prevent rust. The boots should be removed from the skate bag and allowed to air dry in a well-ventilated area. Boot dryers can expedite the drying process and minimize moisture buildup.

Question 4: What are the key indicators suggesting that rivets may require replacement?

Loose rivets, visible corrosion, or signs of wear around the rivet heads indicate the need for replacement. A thorough inspection should be conducted regularly, particularly after high-impact activities. Damaged rivets can compromise the structural integrity of the skates and increase the risk of injury.

Question 5: Is heat molding advisable for all models?

Heat molding is only recommended for models specifically designed for this process. Attempting to heat mold skates not intended for it can cause irreversible damage. Refer to the manufacturer’s guidelines to determine if a particular model is heat moldable.

Question 6: What is the optimal lacing technique for maximizing ankle support?

Lacing should be snug but not overly tight, allowing for ankle flexion. Begin lacing from the bottom up, ensuring even pressure distribution. Lock the laces at the ankle to provide additional support. Waxed laces can help maintain consistent tension throughout the skating session. The use of a “lace bite” pad under the laces can reduce pressure and discomfort.

Consistent attention to these aspects of care and maintenance will optimize performance and extend the lifespan of this equipment.

The subsequent section will provide a glossary of key terms related to skating and associated equipment.

Conclusion

This exploration has provided a comprehensive overview of the features, maintenance, and performance aspects related to the skating equipment. Key areas discussed include boot construction, blade material, ankle support, heat molding, blade sharpening, lace systems, and rivet integrity. Understanding these elements is crucial for maximizing performance, ensuring safety, and extending the lifespan of this specialized equipment.

The information presented is intended to empower informed decision-making regarding equipment selection, maintenance practices, and troubleshooting procedures. Continued adherence to established guidelines and regular equipment assessments are essential for optimal utilization and injury prevention. The principles outlined herein contribute to a safer and more efficient skating experience.