Professional hockey footwear represents a critical piece of equipment for players competing at the highest level. Designed for peak performance, these specialized boots and blades offer unparalleled support, agility, and responsiveness. Examples include models featuring heat-moldable materials for a customized fit, lightweight carbon fiber outsoles for efficient energy transfer, and meticulously engineered steel blades optimized for specific skating styles.

The performance of athletes in a demanding sport depends significantly on their equipment. High-quality construction minimizes the risk of injury and maximizes comfort, allowing players to focus on the game. Advanced blade technology facilitates sharper turns and quicker acceleration, essential for competitive advantage. The evolution of this equipment reflects ongoing innovation driven by the pursuit of enhanced on-ice capabilities and player safety.

The following sections will delve into the key characteristics that distinguish high-performance models. Detailed discussions of blade composition, boot construction materials, and fit customization techniques provide a deeper understanding of the technology behind this essential piece of equipment, and how these features contribute to enhanced athletic performance.

Optimizing Performance with High-Level Hockey Footwear

The following recommendations aim to enhance the performance and longevity of professional-grade equipment used in hockey. Adherence to these guidelines can contribute to improved skating proficiency and equipment durability.

Tip 1: Proper Fit Assessment: Ensure precise fit. Ill-fitting equipment can impede performance and increase the risk of injury. Consult a qualified skate technician for accurate sizing and fitting analysis.

Tip 2: Regular Blade Maintenance: Maintain blade sharpness. Dull blades compromise edge control and gliding efficiency. Sharpen blades at regular intervals, determined by frequency and intensity of use.

Tip 3: Heat Molding for Customization: Utilize heat molding. Many high-end models offer heat-moldable features, allowing for customized fit contours. Follow manufacturer instructions meticulously during the molding process to avoid damage.

Tip 4: Protective Gear Compatibility: Verify compatibility with protective gear. Incompatible equipment can restrict movement and increase vulnerability to impact injuries. Ensure seamless integration with shin guards and other protective elements.

Tip 5: Moisture Management: Address moisture accumulation. Damp conditions can degrade boot materials and promote bacterial growth. Employ moisture-wicking socks and allow boots to air-dry thoroughly after each use.

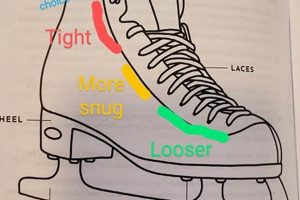

Tip 6: Secure Lacing Techniques: Implement effective lacing techniques. Correct lacing ensures ankle support and prevents slippage. Experiment with different lacing patterns to find the most secure and comfortable fit.

Tip 7: Routine Inspection: Conduct routine inspections. Regularly assess the equipment for signs of wear or damage, including blade cracks, loose rivets, or boot delamination. Promptly address any issues to prevent further deterioration.

Implementing these strategies helps maintain the integrity and functionality of equipment. Consistent application of these tips will facilitate enhanced performance and extend the lifespan of high-performance hockey footwear.

The subsequent sections will examine specific material compositions and technological advancements crucial to understanding the relationship between equipment attributes and player capabilities.

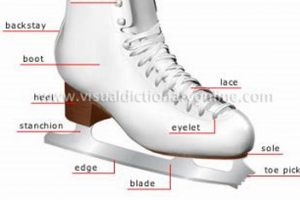

1. Precision Blade Geometry

Blade geometry represents a pivotal characteristic of high-performance equipment, directly influencing an athlete’s ability to execute complex maneuvers with precision and efficiency. The intricacies of blade design are meticulously engineered to optimize performance in the demanding context of professional hockey.

- Radius of Curvature

The radius of curvature dictates the blade’s turning radius. A smaller radius facilitates tighter turns and enhanced agility, while a larger radius promotes stability and gliding efficiency. The selection of an appropriate radius hinges upon individual skating style and preferred on-ice role. Players prioritizing quick pivots typically favor a smaller radius, whereas those emphasizing speed and stability benefit from a larger radius.

- Blade Profile

The blade profile encompasses the distribution of steel along the blade’s length. Variations in profile affect pressure distribution and grip on the ice. A forward-pitched profile enhances acceleration, while a more neutral profile promotes balance and stability. The profile is a critical factor in determining the responsiveness and feel of the equipment.

- Hollow Depth

Hollow depth, or the depth of the concave groove running along the blade’s underside, impacts the blade’s bite and glide characteristics. A deeper hollow provides increased grip, facilitating sharper turns and quicker stops. Conversely, a shallower hollow promotes smoother gliding and reduced friction. The selection of hollow depth is a matter of personal preference, influenced by skating style and ice conditions.

- Blade Pitch

Blade pitch, or the angle of the blade relative to the boot, influences posture and balance. A forward pitch promotes an aggressive stance and enhanced power, while a more upright pitch favors stability and control. Adjustments to blade pitch can optimize energy transfer and reduce fatigue.

Understanding the nuanced relationship between these geometric parameters enables athletes and equipment technicians to fine-tune equipment to specific performance requirements. Precision blade geometry stands as a critical factor in achieving competitive advantage at the highest level of hockey.

2. Ankle Support Integrity

Ankle support integrity within hockey equipment represents a critical safety and performance attribute. The structural stability surrounding the ankle joint directly influences an athlete’s ability to execute complex movements, transfer energy efficiently, and withstand impact forces prevalent in the sport.

- Boot Stiffness and Composition

The materials and construction of the skate boot dictate the degree of ankle stabilization. High-end models often incorporate carbon fiber or reinforced polymers, offering a rigid structure that resists deformation under stress. Insufficient boot stiffness can compromise energy transfer and increase the likelihood of ankle sprains or fractures. Conversely, excessive stiffness may limit range of motion and hinder agility. The selection of materials must balance stability with flexibility to optimize performance while safeguarding the ankle joint.

- Internal Padding and Molding

The internal padding system plays a crucial role in conforming to the unique contours of the athlete’s ankle. Advanced padding materials, such as heat-moldable foams, allow for a customized fit that minimizes slippage and maximizes support. Precise molding ensures uniform pressure distribution, reducing the risk of pressure points and discomfort. Inadequate padding can lead to instability and increased susceptibility to impact injuries. Proper molding and padding are essential for maintaining ankle alignment and preventing excessive pronation or supination during skating.

- Lacing System Configuration

The design and implementation of the lacing system directly impact the level of ankle support. A well-designed lacing system allows for customized tightening across different zones of the boot, enabling athletes to fine-tune the level of support based on their individual needs. Reinforced eyelets and strategically placed lace locks enhance the security and stability of the lacing system. Improperly configured or inadequately tightened laces can compromise ankle stability and increase the risk of injury. Precise lacing techniques are crucial for achieving optimal support and preventing excessive ankle movement.

- Heel Counter Reinforcement

The heel counter, located at the rear of the boot, provides critical support to the heel and ankle. Reinforced heel counters, often constructed from rigid materials like carbon fiber or molded polymers, prevent heel slippage and maintain ankle alignment. A secure heel counter minimizes the risk of ankle instability and enhances energy transfer during push-off. Inadequate heel counter reinforcement can compromise stability and reduce the efficiency of skating strides. The heel counter is an integral component in preserving ankle support integrity.

The interconnectedness of boot stiffness, internal padding, lacing systems, and heel counter reinforcement defines the overall integrity of ankle support. Compromises in any of these areas can negatively impact performance and increase the risk of injury. Continuous advancements in materials and design are aimed at optimizing these features to provide athletes with the highest levels of ankle support and protection.

3. Heat-Moldable Customization

Heat-moldable customization represents a significant advancement in equipment design, directly influencing the fit and performance characteristics of professional hockey footwear. This technology addresses the inherent variability in foot anatomy, enabling a more precise and comfortable interface between the athlete and the equipment.

- Thermoformable Materials

Thermoformable materials, typically composite polymers or specialized foams, constitute the core of heat-moldable customization. These materials exhibit a unique property: they soften and become pliable when exposed to controlled heat, allowing them to conform precisely to the contours of the foot. Upon cooling, the material retains its shape, creating a customized shell that cradles the foot. An example is the use of heat-activated epoxy resins in the outer shell of high-end models, designed to adapt to individual foot shapes.

- The Molding Process

The molding process typically involves heating the skates within a specialized oven or using a directed heat source, such as a heat gun. The athlete then inserts their foot into the heated boot, allowing the thermoformable materials to mold to the foot’s unique anatomy. Pressure may be applied to specific areas to enhance conformity and eliminate pressure points. This process requires careful monitoring to prevent overheating and potential damage to the materials. Improper execution can compromise the structural integrity and intended fit of the equipment.

- Benefits of Customized Fit

A customized fit, achieved through heat molding, offers several advantages. Improved comfort reduces distractions and allows athletes to focus on performance. Enhanced stability minimizes ankle movement within the boot, promoting efficient energy transfer and reducing the risk of injury. Reduced friction prevents blisters and discomfort, particularly during prolonged periods of use. These benefits collectively contribute to enhanced on-ice performance and reduced risk of lower extremity injuries.

- Long-Term Adaptability

While the initial molding process establishes a customized fit, thermoformable materials can exhibit limited adaptability over time. Factors such as repeated use, temperature fluctuations, and moisture exposure can gradually alter the shape and properties of the material. Periodic re-molding may be necessary to maintain the optimal fit and performance characteristics. Regular inspection and maintenance are crucial for preserving the benefits of heat-moldable customization over the lifespan of the equipment.

Heat-moldable customization provides a powerful tool for optimizing the fit and performance of professional hockey footwear. By addressing the individual anatomical variations of athletes’ feet, this technology contributes to enhanced comfort, stability, and overall performance. Proper execution of the molding process and ongoing maintenance are essential for realizing the full benefits of this advanced feature.

4. Impact Force Distribution

Impact force distribution represents a crucial safety feature integrated into professional hockey footwear. The high-impact nature of the sport exposes athletes to significant forces resulting from collisions with other players, the boards, or even errant pucks. Effective distribution of these forces throughout the boot structure mitigates the risk of localized trauma to the foot and ankle. Failure to adequately disperse impact energy can result in contusions, fractures, or more severe musculoskeletal injuries. Thus, the design and materials employed in these skates prioritize the minimization of concentrated stress during on-ice incidents.

Several design elements contribute to optimal impact force distribution. The outer shell, typically constructed from composite materials such as carbon fiber or reinforced polymers, provides a rigid yet resilient structure capable of absorbing and redirecting impact energy. Internal padding systems, often incorporating energy-absorbing foams or gel inserts, further cushion the foot and dissipate forces away from sensitive areas. Strategic placement of these protective elements across the ankle, heel, and metatarsal regions ensures comprehensive coverage against a variety of impact vectors. For instance, many high-end models utilize strategically placed Poron XRD padding in vulnerable areas to absorb and diffuse high-energy impacts.

Understanding impact force distribution within professional hockey footwear is paramount for athletes, equipment managers, and manufacturers. Recognizing the mechanisms by which these skates mitigate trauma enables informed decisions regarding equipment selection, maintenance, and customization. Ongoing research and development efforts focus on refining material properties and structural designs to further enhance impact protection, contributing to the long-term safety and performance of athletes competing at the highest level of hockey. Ultimately, the ability of the skates to effectively manage impact forces is paramount for injury prevention in this physically demanding sport.

5. Energy Transfer Efficiency

Effective energy transfer efficiency within hockey footwear is paramount for maximizing an athlete’s performance potential. The conversion of muscular effort into kinetic energy on the ice directly influences skating speed, agility, and overall endurance. The design and materials of professional hockey footwear are thus critically engineered to minimize energy loss and optimize propulsion.

- Boot Stiffness and Responsiveness

Boot stiffness plays a central role in energy transfer. A more rigid boot minimizes energy dissipation during the stride, ensuring that a greater proportion of the skater’s muscular force is directed into forward motion. High-end models utilize carbon fiber composites to maximize stiffness while minimizing weight. However, excessive stiffness can compromise comfort and increase fatigue. The optimal boot stiffness represents a balance between responsiveness and comfort. An example is seen in models where the lower portion of the boot utilizes stiffer carbon fiber while the upper portion incorporates more flexible materials to allow for greater range of motion.

- Blade Holder Integration

The interface between the boot and the blade holder significantly influences energy transfer. A secure and rigid connection minimizes energy loss at this critical juncture. Advanced blade holder designs often incorporate lightweight, high-strength materials and optimized mounting configurations to maximize energy transfer efficiency. For example, integrated blade holders that are directly molded to the boot chassis can reduce energy loss compared to traditional riveted designs.

- Footbed and Insole Design

The footbed and insole contribute to energy transfer by providing a stable and supportive platform for the foot. A well-designed footbed minimizes foot movement within the boot, reducing energy loss due to slippage and instability. Advanced footbeds often incorporate energy-returning materials that convert impact forces into propulsive energy. For instance, insoles constructed with responsive foams or gel inserts can provide an additional boost during each stride.

- Skate Fit Precision

Precise skate fit is essential for maximizing energy transfer efficiency. Ill-fitting equipment can lead to energy loss due to slippage, instability, and inefficient muscle activation. Heat-moldable customization allows for a personalized fit that minimizes dead space within the boot, ensuring that the athlete’s muscular force is directly translated into propulsion. A snug and supportive fit prevents the foot from moving independently of the boot, optimizing energy transfer with each stride.

The integration of these facetsboot stiffness, blade holder integration, footbed design, and skate fitcollectively determines the energy transfer efficiency of professional hockey footwear. Advances in materials science and engineering continue to drive improvements in these areas, enabling athletes to maximize their on-ice performance.

Frequently Asked Questions

This section addresses common inquiries concerning professional-grade hockey footwear. The following information is intended to provide clarity and dispel misconceptions regarding this critical piece of athletic equipment.

Question 1: What distinguishes equipment used by professional players from recreational models?

Professional-level models incorporate advanced materials and construction techniques to maximize performance and protection. Key differences include stiffer boot construction for enhanced energy transfer, precision blade geometry for superior control, and heat-moldable customization for optimal fit. Recreational models typically prioritize comfort and affordability over peak performance characteristics.

Question 2: How frequently should blades be sharpened to maintain optimal performance?

Sharpening frequency depends on several factors, including ice conditions, skating frequency, and individual preferences. As a general guideline, blades should be sharpened every 5-10 hours of ice time. Dull blades compromise edge control and gliding efficiency, potentially increasing the risk of injury.

Question 3: What is the significance of blade radius and hollow depth in skate performance?

Blade radius influences turning agility and stability, while hollow depth affects grip and glide. A smaller radius facilitates tighter turns, while a deeper hollow provides enhanced edge control. The selection of appropriate radius and hollow depth depends on an athlete’s skating style and on-ice role. Improper selection can impede performance.

Question 4: How should equipment be properly maintained to prolong its lifespan?

Proper maintenance includes regular blade sharpening, thorough drying after each use, and periodic inspection for signs of wear or damage. Moisture accumulation can degrade boot materials and promote bacterial growth. Promptly addressing any issues, such as loose rivets or blade cracks, can prevent further deterioration.

Question 5: Can equipment be effectively customized to accommodate individual foot anatomies?

High-end models often feature heat-moldable materials that allow for customized fit contours. Heat molding ensures uniform pressure distribution, reduces friction, and enhances stability. Consulting a qualified skate technician for proper fitting and molding is essential for optimal results.

Question 6: What are the risks associated with using improperly fitted equipment?

Improperly fitted equipment can compromise performance, increase the risk of injury, and lead to discomfort. Ill-fitting skates can cause blisters, reduce stability, and impede energy transfer. Precise fit assessment and customization are crucial for maximizing performance and preventing injuries.

The information provided above serves as a basic guide to understanding key aspects of NHL ice skates. Consultation with equipment professionals and careful consideration of individual needs are encouraged for optimal selection and maintenance.

The following section will address the importance of material science in the design and construction of this equipment.

NHL Ice Skates

This exploration has detailed the critical features defining professional-caliber hockey footwear. Key elements such as blade geometry, ankle support, heat-moldable customization, impact force distribution, and energy transfer efficiency were examined, emphasizing their combined effect on athlete performance and safety. The analysis has underscored the intricate interplay between materials science, engineering design, and biomechanical function within this essential equipment category.

Continued advancements in materials and manufacturing will undoubtedly drive further innovation in equipment design. A deeper understanding of these technologies is paramount for athletes, equipment managers, and manufacturers alike. Vigilant equipment selection, meticulous maintenance practices, and awareness of emerging technologies will continue to contribute to enhanced on-ice performance and reduced risk of injury. Therefore, ongoing engagement with these developments remains crucial for the continued evolution of the sport.