The process encompasses the methods and techniques employed in crafting beverages within a specific coastal urban environment known for its surfing culture. It involves the selection of ingredients, the application of brewing processes, and the distribution of the resulting product within that locale. This methodology can be seen in local coffee roasters meticulously selecting beans and tailoring their roasting profiles to suit the tastes of residents and tourists alike.

The significance of this endeavor lies in its contribution to the local economy, its role in shaping community identity, and its potential for promoting sustainable practices. The unique character of beverages produced reflects the area’s natural resources, historical influences, and the innovative spirit of local artisans, all of which contributes to a distinct regional brand. These practices allow the community to celebrate local character and preserve heritage.

The following discussion will delve into specific aspects, including local sourcing strategies, popular beverage styles, and the impact of tourism on the brewing landscape. Further analysis will cover challenges faced by local producers and opportunities for future growth and innovation within this specialized market.

Brewing Recommendations

The following provides practical advice derived from experience within the specified locale, targeting those engaged in beverage production.

Tip 1: Source Ingredients Locally: Prioritize the procurement of materials from regional suppliers. This reduces transportation costs, supports local agriculture, and allows for the creation of unique flavor profiles reflective of the area’s terroir. An example would be utilizing honey from local apiaries to sweeten craft sodas.

Tip 2: Optimize Water Chemistry: Analyze and adjust the water profile to suit the desired beverage style. Water composition significantly impacts flavor extraction and overall quality. Water adjustments for specific beer styles should be carefully executed.

Tip 3: Implement Strict Sanitation Protocols: Maintain a rigorous cleaning and sanitizing schedule to prevent contamination and ensure product consistency. The brewing environment must be thoroughly disinfected at regular intervals.

Tip 4: Control Fermentation Temperature: Monitor and regulate fermentation temperatures closely to achieve optimal yeast performance and prevent undesirable off-flavors. Temperature control is crucial for producing consistent brews.

Tip 5: Invest in Quality Equipment: Utilize durable and reliable brewing apparatus to enhance efficiency, reduce downtime, and improve the final product. Using proper equipment can make a difference.

Tip 6: Practice Responsible Waste Management: Implement strategies to minimize waste generation and promote sustainability, such as composting spent grains and recycling packaging materials. Sustainable practices help promote environmental stewardship and cost reduction.

These recommendations emphasize the importance of local resources, quality control, operational efficiency, and sustainability. Adherence to these guidelines can improve product consistency, reduce operational costs, and enhance brand reputation.

The subsequent sections will explore advanced brewing techniques and strategies for market expansion.

1. Local Ingredient Sourcing

Local ingredient sourcing represents a fundamental component of beverage production within a specific coastal urban area. It directly influences product distinctiveness, economic sustainability, and community engagement. Its strategic implementation impacts various facets of the brewing process, shaping the final product and its market position.

- Terroir Expression

The utilization of regionally cultivated ingredients imparts unique flavor profiles that reflect the area’s climate, soil, and overall environment. This creates a sense of place within the beverage, distinguishing it from mass-produced alternatives. For instance, a beer brewed with locally grown hops will exhibit characteristics specific to the region, offering a taste distinct from beers using imported hops.

- Economic Impact on Local Agriculture

Procuring resources from regional farms and producers provides direct financial support to the local agricultural sector. This creates a symbiotic relationship where the brewery benefits from fresh, high-quality ingredients, and local farmers gain a reliable market for their products. This contributes to the economic stability of the community and encourages sustainable agricultural practices.

- Reduced Carbon Footprint

Minimizing the distance raw materials travel from their source to the production facility significantly reduces transportation emissions. This aligns with environmental sustainability goals and appeals to environmentally conscious consumers. Local sourcing presents tangible benefits.

- Brand Differentiation and Authenticity

Emphasizing the use of regional ingredients enhances brand perception and consumer trust. It positions the beverage as a handcrafted, authentic product with a connection to the local community. This appeal to consumers who seek unique and locally sourced products fosters loyalty and drives sales.

The strategic integration of local ingredient sourcing enhances beverage quality, supports the regional economy, and promotes brand authenticity, all of which are key considerations when determining how you brewin surf city, providing a framework for successful and sustainable operations.

2. Water Profile Adjustment

Water profile adjustment represents a critical factor within beverage production. The mineral composition of water directly affects flavor extraction, enzymatic activity, and overall quality. In brewing operations, particularly when considering how to brew within the context of surf city, understanding and manipulating the water profile becomes essential for achieving desired product characteristics. Different water profiles are suited to varying beverage styles; pale ales require water high in sulfates to accentuate hop bitterness, while stouts often benefit from water with a higher bicarbonate content to enhance malt flavors. The failure to adjust the water profile can lead to suboptimal flavor development, inconsistent batch results, and a product that fails to meet quality standards. For example, breweries located in areas with naturally soft water must add minerals like calcium sulfate (gypsum) or calcium chloride to create water profiles suitable for specific beer styles.

The practical application of water profile adjustment involves analyzing the existing water source and calculating the necessary mineral additions to achieve the target profile. This requires a working knowledge of water chemistry, an understanding of the interactions between different minerals and brewing ingredients, and access to appropriate water treatment equipment. Tools such as brewing calculators and water analysis reports are indispensable for making informed decisions. Furthermore, consideration must be given to the consistency of the water source. Seasonal variations in water composition necessitate regular monitoring and adjustment to maintain product consistency throughout the year. Some craft brewers meticulously filter their water to remove any unwanted impurities, then reconstruct it with the desired mineral content for precise flavor control.

In summary, water profile adjustment significantly impacts the final product. Neglecting this aspect compromises beverage quality and consistency. Understanding how to manipulate water chemistry is vital for consistent product quality. The complexities demand a careful approach, blending scientific analysis with practical brewing expertise to achieve optimum outcomes. Mastering water profile adjustment is an ongoing challenge that directly impacts how you brewin surf city.

3. Temperature Control Precision

Temperature control precision is a fundamental aspect of beverage production and an important parameter of “how you brewin surf city.” Accurate temperature management at various stages directly impacts flavor development, fermentation efficiency, and product consistency. Neglecting this aspect can result in off-flavors, stalled fermentations, and products that fail to meet quality standards.

- Fermentation Phase Regulation

During fermentation, maintaining optimal temperatures for specific yeast strains is paramount. Too high, and undesirable esters and fusel alcohols may develop, imparting harsh or solvent-like flavors. Too low, and the fermentation may stall, resulting in incomplete sugar conversion and a sweet, unfinished product. For example, lagers typically ferment at lower temperatures (45-55F) than ales (60-72F), each range promoting distinct flavor profiles. In the context of “how you brewin surf city”, a brewery specializing in diverse beer styles requires precise temperature control systems for simultaneous fermentations of multiple batches.

- Wort Cooling Efficiency

Rapid and efficient cooling of wort after boiling is essential to prevent the growth of unwanted bacteria and to achieve the optimal temperature for yeast pitching. Inadequate cooling can lead to contamination and off-flavors, while overly rapid cooling can shock the yeast. Coastal climates, as in surf city, may present challenges for wort cooling due to higher ambient temperatures and humidity, necessitating robust cooling systems. Local breweries must account for these regional variations in their temperature control strategies.

- Cold Storage Stabilization

Maintaining consistent cold storage temperatures after fermentation is crucial for stabilizing flavors and preventing further fermentation or spoilage. Fluctuations in temperature can lead to haziness, off-flavors, and reduced shelf life. In “how you brewin surf city,” where tourism and seasonal demand may lead to fluctuating inventory levels, reliable cold storage is imperative to ensure consistent product quality for consumers.

- Pasteurization and Sterilization Processes

For certain beverage styles or product lines, pasteurization or other sterilization techniques may be employed to extend shelf life and prevent microbial contamination. These processes require precise temperature control to effectively eliminate pathogens without compromising flavor or nutritional value. In “how you brewin surf city”, if bottled or canned products are distributed regionally or nationally, strict temperature control during pasteurization is critical to comply with food safety regulations and maintain brand reputation.

In summary, temperature control precision is a critical element influencing the quality and consistency of beverages within the operational framework of “how you brewin surf city”. Efficient temperature management requires investment in appropriate equipment, meticulous monitoring procedures, and comprehensive training for brewing staff to mitigate risks and optimize brewing outcomes.

4. Sanitation Protocol Adherence

Sanitation protocol adherence represents a non-negotiable component of “how you brewin surf city.” The coastal environment and tourism present unique contamination risks, necessitating rigorous and comprehensive cleaning practices. Failure to maintain strict sanitation standards can result in microbial spoilage, off-flavors, and potential health hazards, severely impacting product quality and brand reputation. The consequences extend beyond mere product imperfections; they encompass potential recalls, legal liabilities, and damage to consumer trust. For instance, a popular brewery in a coastal town experienced a severe setback when a wild yeast contamination led to the recall of several batches of its flagship beer, resulting in significant financial losses and tarnished brand image. This underscores the practical significance of stringent sanitation practices as an integral facet of brewing operations, especially within the context of “how you brewin surf city”.

The implementation of effective sanitation protocols involves a multi-faceted approach encompassing regular cleaning schedules, the utilization of appropriate sanitizing agents, and comprehensive training for all personnel involved in the brewing process. All surfaces and equipment that come into contact with wort or beer, including fermenters, tanks, hoses, and bottling lines, must be thoroughly cleaned and sanitized before each use. Chemical sanitizers, such as peracetic acid and quaternary ammonium compounds, are commonly employed, but their effectiveness depends on proper concentration, contact time, and rinsing procedures. Furthermore, the design of brewing equipment plays a crucial role in sanitation efficacy; equipment with smooth, easily accessible surfaces minimizes the risk of bacterial or yeast buildup. Regular inspections and audits are essential to verify that sanitation protocols are consistently followed and that any potential issues are promptly addressed. An example of proactive sanitation is the implementation of a clean-in-place (CIP) system for fermenters and tanks, which automates the cleaning and sanitizing process, reducing the risk of human error and ensuring consistent results.

In summary, the connection between sanitation protocol adherence and “how you brewin surf city” is direct and profound. Rigorous sanitation practices are not merely a recommendation but a fundamental requirement for producing safe, high-quality beverages in a potentially challenging environment. The commitment to sanitation demands a proactive and systematic approach, encompassing comprehensive training, meticulous cleaning procedures, and ongoing monitoring to mitigate risks and safeguard product integrity. Neglecting sanitation protocols undermines all other brewing efforts and can lead to irreversible damage to a brewery’s reputation and financial stability.

5. Waste Reduction Strategies

Waste reduction strategies constitute an indispensable element of sustainable operations and a key consideration within the framework of “how you brewin surf city”. The brewing process inherently generates substantial waste streams, including spent grains, trub, yeast slurry, and packaging materials. Inadequate waste management not only contributes to environmental degradation but also results in increased operational costs and potential regulatory penalties. A brewery’s commitment to waste reduction directly reflects its environmental responsibility and its long-term financial viability within the competitive beverage market. The integration of waste reduction measures directly impacts efficiency and overall output. One large brewery, for instance, significantly reduced its water usage and waste generation by implementing a closed-loop cleaning system, which minimized water consumption and recovered valuable by-products from the brewing process. This demonstrates the practical significance of integrating waste reduction into all phases of the production process.

Effective waste reduction strategies encompass several key areas. Spent grain, a primary byproduct, can be repurposed as animal feed, compost material, or even biofuel. Trub, the sediment formed during wort boiling, can be used as a soil amendment or as a component in biogas production. Yeast slurry, after proper treatment, can be converted into animal feed or used as a source of enzymes. Packaging materials, such as bottles, cans, and cardboard, should be recycled or reused whenever possible. Moreover, optimizing brewing processes to minimize waste generation at the source is crucial. Implementing water conservation measures, such as dry floor cleaning and efficient cleaning systems, reduces water consumption and wastewater discharge. In terms of “how you brewin surf city”, an environment where sustainability is often valued by residents and tourists, the adoption of these practices aligns with consumer expectations and enhances brand reputation. For example, breweries that actively promote their waste reduction initiatives often attract environmentally conscious consumers and gain a competitive edge in the market.

In summary, waste reduction strategies are intrinsically linked to “how you brewin surf city,” signifying a commitment to environmental sustainability and operational efficiency. Effective waste management practices not only minimize environmental impact but also reduce costs, enhance brand reputation, and ensure long-term financial viability. Despite the challenges involved in implementing comprehensive waste reduction programs, the benefits far outweigh the costs, making it an essential component of responsible brewing operations. The successful integration of waste reduction requires a holistic approach, encompassing process optimization, byproduct utilization, and a commitment to continuous improvement.

Frequently Asked Questions

The following addresses common inquiries related to beverage production, specifically within the context of “how you brewin surf city,” aiming to provide clarity and insight into prevailing practices and challenges.

Question 1: What specific challenges does the coastal environment of “surf city” pose to the brewing process?

The proximity to the ocean introduces several challenges, including higher humidity levels that can affect fermentation control and increased salinity in water sources, potentially impacting the flavor profile of beverages. Coastal climates also tend to exhibit greater temperature fluctuations, requiring more robust temperature control systems during fermentation and storage.

Question 2: How does local ingredient sourcing contribute to the distinctiveness of beverages produced in “surf city”?

Sourcing ingredients locally, such as regional hops, fruits, and honey, imparts unique flavor characteristics reflective of the area’s terroir. This contributes to a distinct regional identity for beverages, differentiating them from mass-produced alternatives and appealing to consumers seeking authentic, locally crafted products.

Question 3: What specific sanitation measures are essential for maintaining product quality in the context of “how you brewin surf city”?

Given the potential for increased microbial contamination in coastal environments, stringent sanitation protocols are paramount. This includes regular cleaning and sanitizing of all equipment, water purification systems to remove impurities and salinity, and comprehensive training for personnel on proper sanitation procedures.

Question 4: How does the influx of tourism impact the brewing landscape of “surf city”?

Tourism significantly influences the demand for beverages, often leading to seasonal fluctuations in production and inventory management challenges. It also necessitates the development of diverse product lines to cater to varied consumer preferences and the implementation of efficient distribution networks to reach both local and tourist populations.

Question 5: What strategies are employed to minimize waste generation within the brewing operations of “surf city”?

Breweries often implement waste reduction strategies, including spent grain repurposing as animal feed or compost, trub utilization as a soil amendment, and recycling of packaging materials. Water conservation measures, such as dry floor cleaning and efficient cleaning systems, are also implemented to reduce water consumption and wastewater discharge.

Question 6: How can breweries adapt to potential changes in water availability due to climate change in “surf city”?

Strategies include investing in advanced water treatment technologies, such as reverse osmosis, to improve water quality and reduce water consumption. Implementing rainwater harvesting systems and exploring alternative water sources, such as recycled water, can enhance water security and reduce reliance on municipal water supplies.

These responses underscore the multifaceted considerations involved in beverage production within the specific context of “how you brewin surf city.” Attention to environmental factors, ingredient sourcing, sanitation, tourism, waste reduction, and water management is crucial for sustained success.

The subsequent section will delve into advanced brewing techniques and strategies for market expansion within this unique environment.

Conclusion

This exploration of how you brewin surf city has illuminated the nuanced interplay of factors inherent in crafting beverages within this unique environment. The discussion has spanned the critical role of local sourcing, the imperative for precise water profile adjustment and temperature control, the unwavering necessity of sanitation protocol adherence, and the mounting importance of comprehensive waste reduction strategies. These elements are not isolated considerations but rather interconnected facets of a holistic brewing approach tailored to the specific challenges and opportunities presented by the coastal urban setting.

The continued success and sustainability of beverage production hinge upon a rigorous commitment to these principles. Future endeavors should focus on fostering innovation in water conservation techniques, exploring novel applications for brewing byproducts, and actively engaging with the local community to promote responsible consumption. By embracing these challenges and opportunities, breweries can not only thrive within the dynamic landscape of surf city but also contribute to a more sustainable and vibrant future for the region.

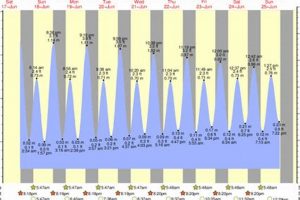

![Surf City NJ Tide Chart: Your Daily Guide [Updated] Learn to Surf & Skate: A Beginner's Step-by-Step Guide Surf City NJ Tide Chart: Your Daily Guide [Updated] | Learn to Surf & Skate: A Beginner's Step-by-Step Guide](https://universitysurfandskate.com/wp-content/uploads/2026/02/th-38-300x200.jpg)